What are MIM Parts?

Introduction

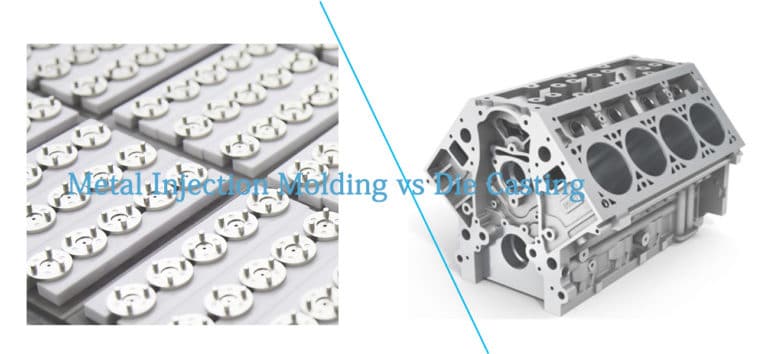

What are MIM Parts? MIM Parts refers to metal components produced by metal injection molding process. MIM (Metal Injection Molding) is a new metalworking technology. Comparing to those well-established metalworking technology, such as forging, die casting, CNC machining. MIM has better performance for small size, complex structure metal components with large quantity. ZCMIM produce various MIM parts in a wide range of materials, our common MIM materials including: Ferrous alloys, Tungsten alloys, Nickel alloys, Molybdenum alloys, Titanium alloys, etc.

MIM Parts Advantages

Metal injection molding applies raw materials of feedstock, which is combine of fine-powdered metal and binder materials. Then these feedstocks will be molten and formed into different shapes with complex structure in injection molding process. This molding process applies high tolerance and multiple cavities to produce high volume molded parts (green parts) in one step. After molding, we remove binder materials in debinding process (brown parts), and densify metal powders in sintering process. Finally, we will get net-shape metal parts with high density of 98%.

Easy Material Alternative

MIM process normally uses feedstock with fine-powered metal particles. Therefore, We can select different feedstock with different metal alloy powders to produce various MIM components with different metal. Regardless of other implement factors, we are able to produce same structure MIM products with different metal materials easily. There is only sintering temperature issue to consider for final parts performance without any other additional time and money cost. This is very cost-effective for MIM project in new products development and products performance improvement.

Convenient Post-manufacturing

MIM parts have the same physical and chemical properties as raw metal alloys. So any post operations on forging or casting parts can be applied on MIM components. Such as welding, soldering, hardening, tempering, polishing, machining and milling. All these post-operations will increase surface performance of physical and mechanical properties.

In most case, sintered parts can satisfy all customers requirements, such as, tensile strength, yield strength, surface hardness, etc. However, for specific demands, we can apply polishing technology to improve surface roughness, heat-treatment to improve hardness, tempering to improve elongation.

Micro MIM Parts Size

Different from other traditional metalworking technologies, powered metallurgy and metal injection molding are both suitable for micro metal parts. However, MIM parts have more complex geometry structure than PM parts.

As we can see in the following picture of micro MIM product, its length is only 1.46 mm.

High Tolerance

MIM technology is suitable for small size metal parts, therefore, MIM parts are small size with higher tolerance than traditional metal components. Normally, MIM components are applied in Automotive, Electrical, Medical and other industrial devices. Regardless of common mechanical properties’ requirement, tolerance is the key characteristic impact final function performance. MIM parts have tolerance of ±0.3%-0.5% nominally, this can satisfy normal functional demand in most case. Furthermore, for special tighter tolerance, we apply additional secondary operations to improve final tolerance as requirements. Otherwise, this will give rise to additional cost and time.

Parts Consolidation

MIM parts have complex structure with less limitation than Die casting, PM, machining, Forging parts. Therefore, metal injection molding technology can produce just one single part without further different parts assembly. In products R&D process, researchers can consolidate different parts into one single parts, in order to save weight, cost and time. Furthermore, parts consolidation will improve strength and performance. In fact, MIM components are more close to original design intent than parts assembly.

MIM Parts Limitation

High Investment

Although metal injection molding is a cost-effective metalworking technology, there is high investment in the beginning of new projects. In reason of high tolerance and complex geometries of MIM parts, we require precise molds for further injection molding process. Therefore, the cost of MIM tooling is higher than other technologies like PM, Die casting. In addition, the raw materials of MIM are also more expensive than PM, Die casting, and machining. The feedstock in MIM process contains finer metal powder (2-15 micron) than PM (50-100 micron).

Technology Experience

Because of high tolerance and complex geometries in MIM parts, its manufacturing process requires excellent experience in every step with precise control. In MIM manufacturing process, we should consider any elements from feestock selection, injection molding, debinding, sintering to final post-operation.

Feestock Selection

Normally, our customers will determine the metal alloy types with according properties. Otherwise, we also need to recommend the most suitable MIM material for our customers. The MIM material will achieve not only mechanical properties in demand, but also further performance of surface and second-operation.

Injection Molding

Our engineering team will analyze MIM parts geometry structure in design process. In order to ensure possibility of injection molding. There are various factors to be considered for actual injection molding, such as parting lines, undercuts, draft angle, etc.

Debinding

The dramatic shrinkage will occur in debinding process, the shrinkage rate will be affected by both materials, debinding temperature and time. Therefore, we should be familiar with MIM material shrinkage data from finished projects. In addition, we also need to control debinding temperature and time precisely. Our experienced team will fix any challenges and issues in debinding process.

Sintering

The sintering process will determine the physical and chemical properties of MIM parts. It requires our engineering team to prepare the perfect sinter schedule according to specific MIM materials. All data of sintering temperature and time is from previous projects with similar MIM materials, injection molding and debinding.

Post-operation

To consider final usage of MIM products, we should apply different post-operation to improve mechanic or other performance. Or no post-operation is needed sometimes. All these decision should be confirmed before start MIM production. This encourages manufacturers to have more experience in similar projects. They are able to produce MIM parts with required properties and tolerance.

Conclusion

All in all, MIM Parts are normally in small size with complex geometries. Its wide materials options make it popular in various industries. However, MIM manufacturing is more difficult and complicated than other technologies. Therefore, MIM components require professional engineering team and experienced factory to achieve the best performance.

Contact ZCMIM team now to confirm whether your new design is MIM part?