Tool Steel MIM

Introduction

Tool steels have significant potential applications in MIM industry and MIM-like manufacturing process. These steels can be formed via both prealloy and mater alloy routes. The common MIM tool steels including: D2, M2, AISI8620, H11, H13, S7 and T15. All these tool steels are sintered in nitrogen atmosphere.

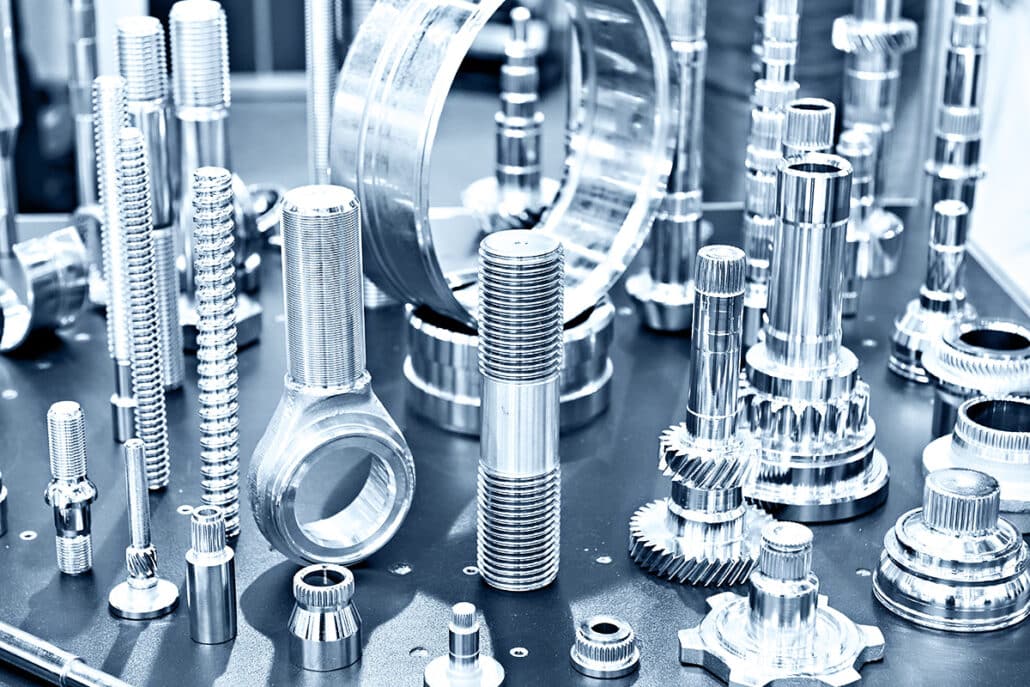

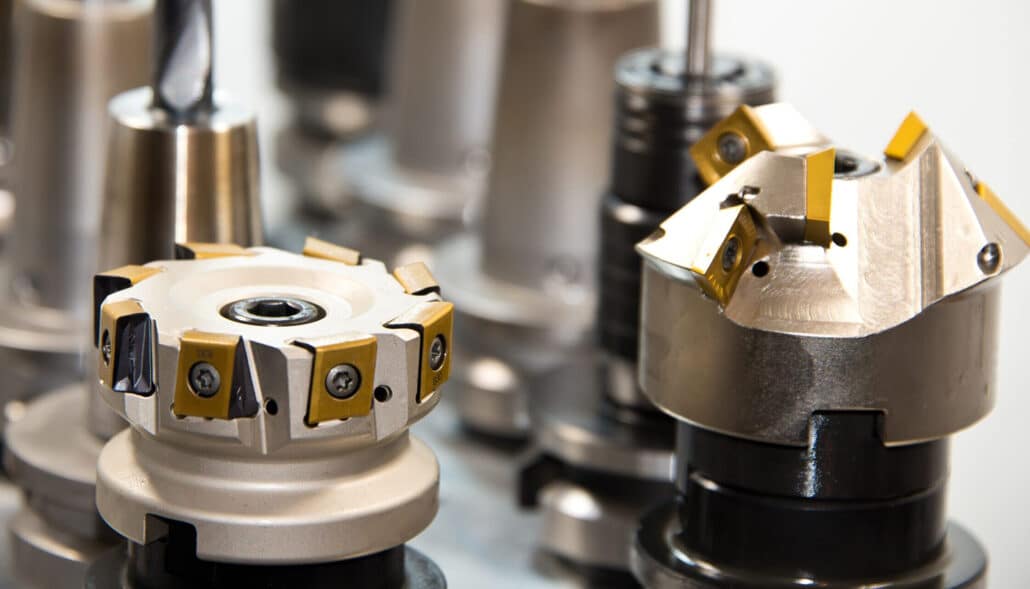

Metal injection molding is well-suited to hard metals with complex shapes, where CNC machining is unfeasible or extremely expensive. Tool steels with MIM process can produce specific industrial applications with high hardness and wear resistance. Tool steels have typical carbon content in range of 0.4-1.5%, heating treatment with careful controlling can achieve optimum distribution of matrix carbide, then provide required wear performance.

For more severe environments, higher levels of refractory carbide form with W, Mo are applied to achieve hot hardness and abrasion resistance. M2 is a high-speed tool steel in MIM process with wide application, although it has challenges in narrow sintering window.

Sintering Mechanism

The sintering mechanism of M2 and other high Carbon tool steel is Super-Solidus Liquid Phase Sintering (SSLPS). In SSLPS, the desification proceed rapidly once the grain boundaries reach to a liquid phase. Grain growth also occur rapidly as liquid film thickness increase, but this also increase the likelihood of distortion.

Case hardening steels and maraging steels are also adopted for tooling application. For the tough core and surface hardness, AISI 8620 with low carbon can reach to 60HRC after post-sintering carburizing treatment. Maraging steel 18Ni300 can develop high hardness of 55HRC after heat treatment.

For any tooling steels, the carbon losses in sintering are quite modest, predictable, and compensated. In order to achieve required properties with according carbon contents.

Properties of Tool Steel

The most common tool steels in MIM are H13, S7, A2, M2, D2, T15. These alloys provide increasing hardness with increasing carbon content. The alloy choice for specific applications depend on working temperature, surface hardness, strength, shock resistance, toughness requirement, cost. There are six groups of carbon-containing tool steels: water-hardening, cold-work, shock-resisting, high-speed, hotwork and special purpose types.

In numerous previous studies, the mater alloy approach can achieve higher density and lower distortion. In addition, the critical carbon control will determine final sintering behavior and finished properties. The following table shows common melting and solidification ranges of several tool steels.

| Materials | Melt Onset (℃) | Melt Peak (℃) | Solidification Onset (℃) |

| MIM 8620 | 1470-1480 | 1480-1490 | 1472-1480 |

| MIM H11 | 1410-1420 | 1460-1475 | 1470-1480 |

| MIM H13 | 1375-1390 | 1477-1483 | 1468-1472 |

| MIM S7 | 1372-1411 | 1475-1485 | 1470-1480 |

| MIM T15 | 1466-1470 | 1493-1497 | 1487-1490 |

H11, and H13 are tough, high-strength tool steels for hot work environments like extrusion and forging dies. S7 has high hardness and good impact toughness, it is applied in plastic injection, compression and transfer moulds and componentry including core and ejector pins. T15 is a highly alloyed tool steel, it is applied in high-performance broaches, milling cutters, end mills, taps and reamers. MIM tooling is made from harden steel of S7 or H13. The high V content can increase wear resistance, while W(Tungsten), Co(Cobalt) can improve high temperature performance.

MIM 8620

8620 Chemical Composition

| MIM 8620 | Iron | Manganese | Nickel | Chromium | Carbon | Silicon | Molybdenum | Sulfur | Phosphorus |

| Percent by Weight | BaL. | 0.70-0.90 | 0.40-0.70 | 0.40-0.60 | 0.18-0.23 | 0.15-0.35 | 0.15-0.25 | 0.04 | 0.035 |

8620 Mechanical Properties

| Material | Density | Tensile Strength | Yield Strength(0.2%) | Impact Strength | Hardness | Elongation(% in 25.4mm) |

| MIM 8620 | ≥7.85g/cm³ | ≥550 Mpa | ≥330 Mpa | 190J | 80 HRB | ≥40% |

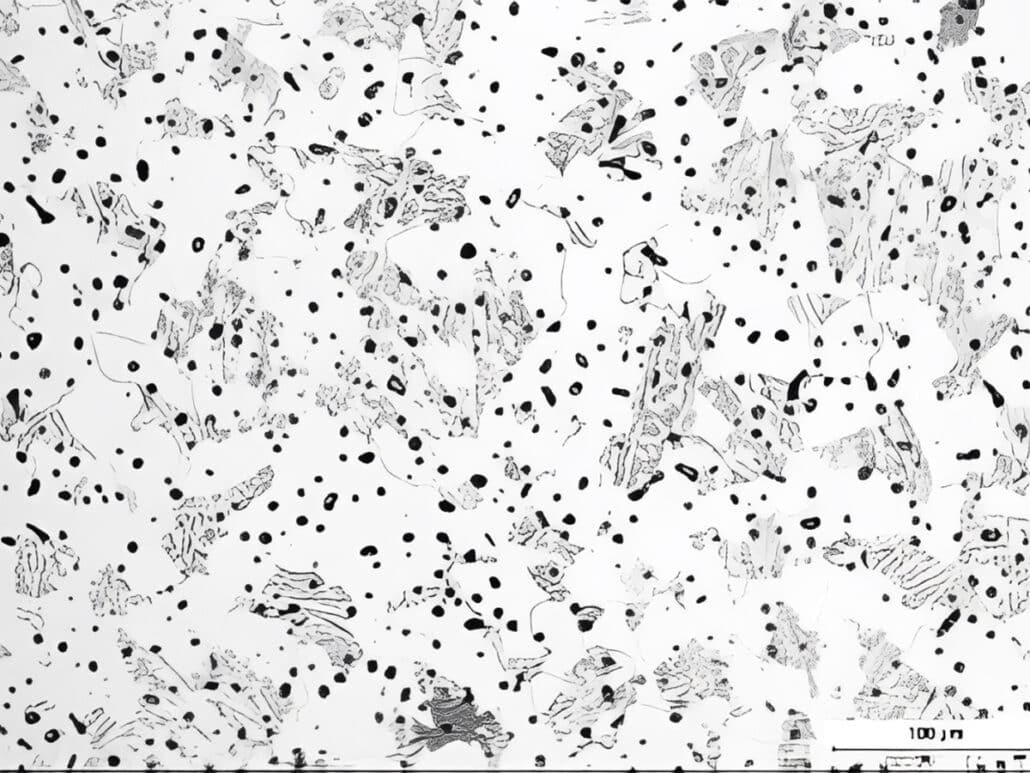

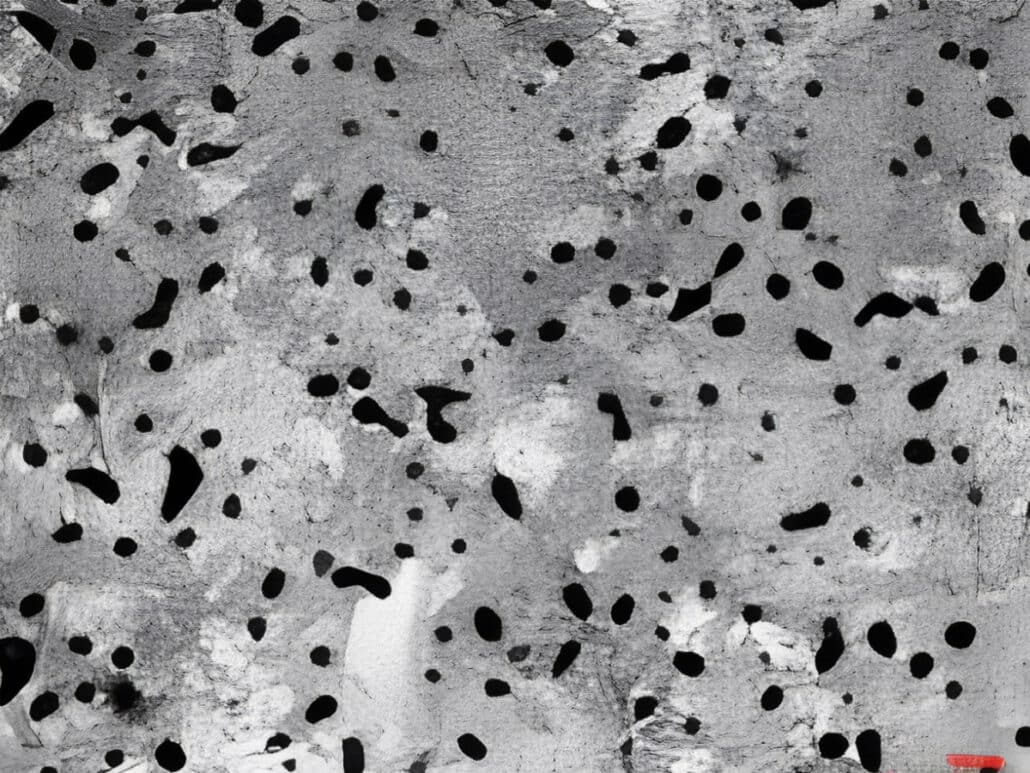

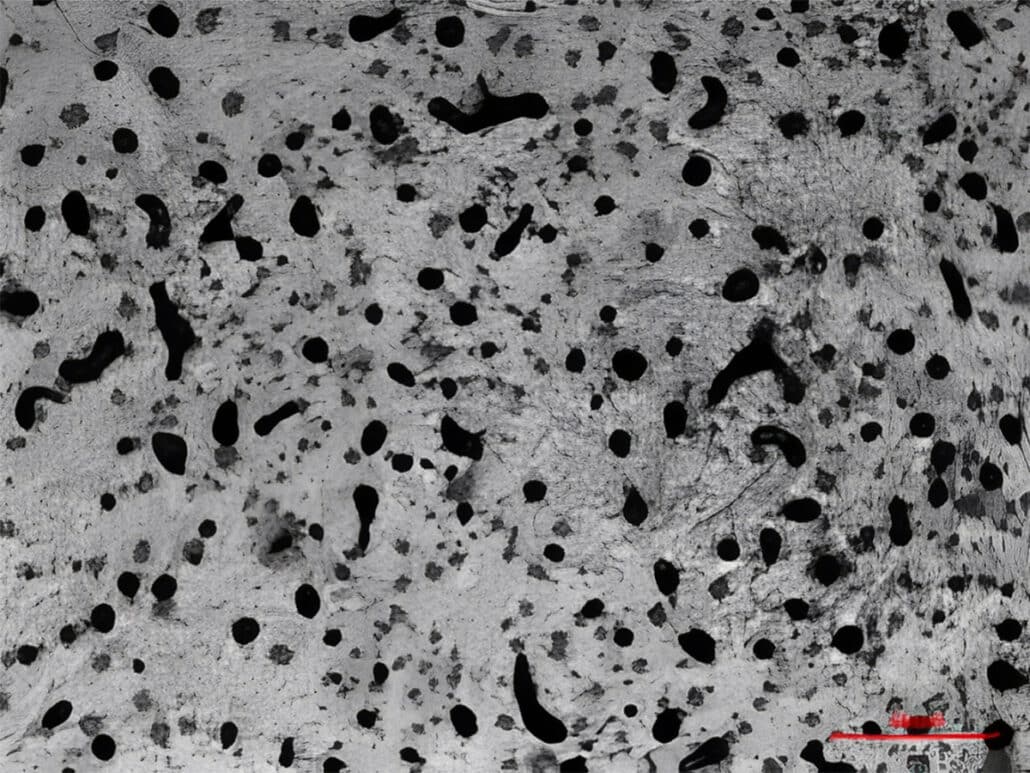

The prealloy of MIM 8620 can achieve 93% theoretical density, while mater alloy with same composition can reach over 95%. From the following metallographic section of sintered 8620, there are mixed structure of ferrite and fine pealite. The mater alloy variant provide a lower level of porosity and a coarser grain size, the pores are fine and dispersed evenly.

Sintered 8620

Heat-treated 8620

MIM M2

M2 Chemical Composition

| MIM M2 | Iron | Tungsten | Molybdenum | Vanadium | Carbon | Nickel | Silicon | Chromium | Manganese | Copper |

| Percent by Weight | BaL. | 5.50-6.75 | 4.50-5.50 | 1.75-2.20 | 0.78-1.05 | 0.30 | 0.20-0.45 | 0.20-0.45 | 0.15-0.40 | 0.25 |

M2 Mechanical Properties

| Material | Density | Melting point | Tensile Strength | Yield Strength(0.2%) | Hardness | CTE (20-500 ℃) |

| MIM M2 | ≥8.16g/cm³ | 1420℃ | ≥1400Mpa | ≥1200 Mpa | 54 HRC | 12.2 μm/m°C |

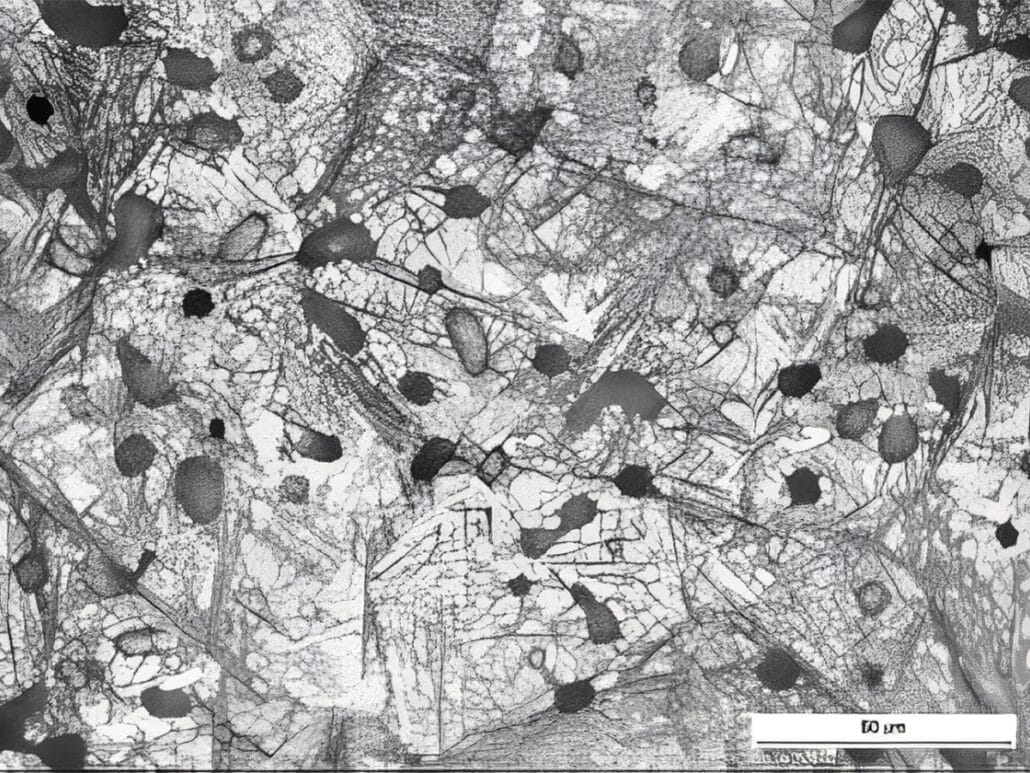

M2 steel is molybdenum high speed tool steel, it has high carbon content and better wear resistance. M2 steels can be hardened by tempering and quenching. The M2 tempering at 565.5°C can reach harness from 60 to 65 HRC.

Sintered M2

MIM H11

H11 Chemical Composition

| MIM H11 | Iron | Chromium | Molybdenum | Nickel | Vanadium | Carbon | Silicon | Manganese | Sulfur | Phosphorus |

| Percent by Weight | BaL. | 4.75-5.50 | 1.10-1.60 | 0.30 | 0.30-0.60 | 0.33-0.43 | 0.80-1.20 | 0.20-0.50 | 0.03 | 0.03 |

H11 Mechanical Properties

| Material | Density | Melting point | Tensile Strength | Yield Strength(0.2%) | Hardness | Thermal expansion (20-100 ℃) |

| MIM H11 | ≥7.81g/cm³ | 1427℃ | ≥1200Mpa | ≥1000 Mpa | 53 HRC | 11.9 x 10-6/℃ |

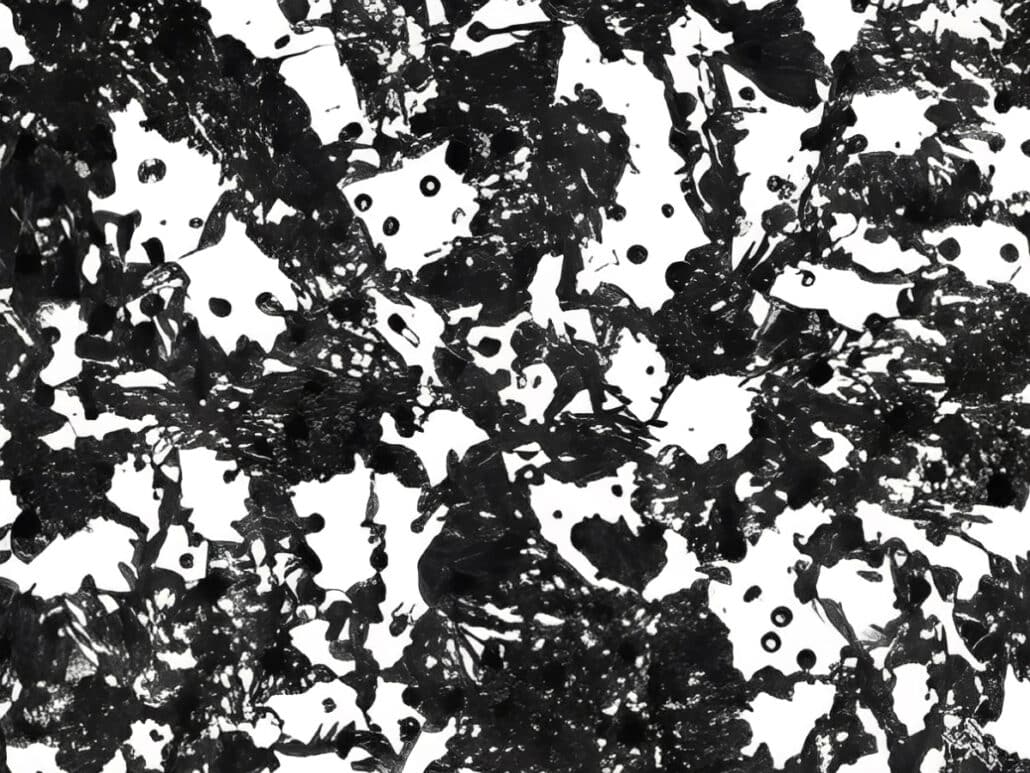

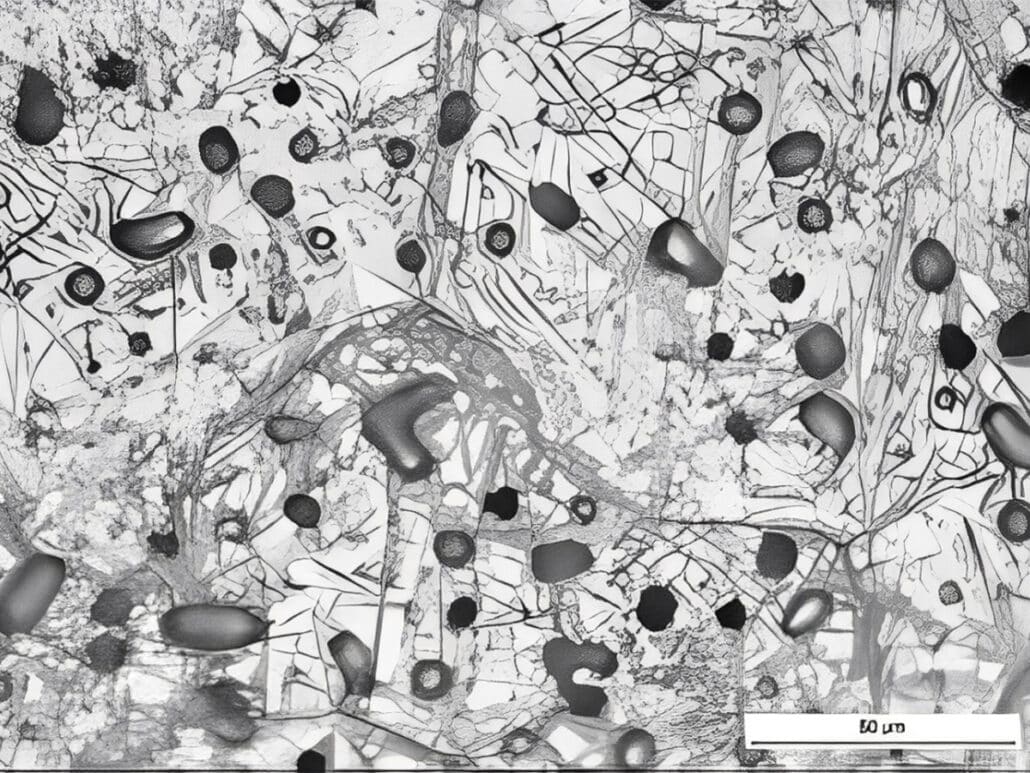

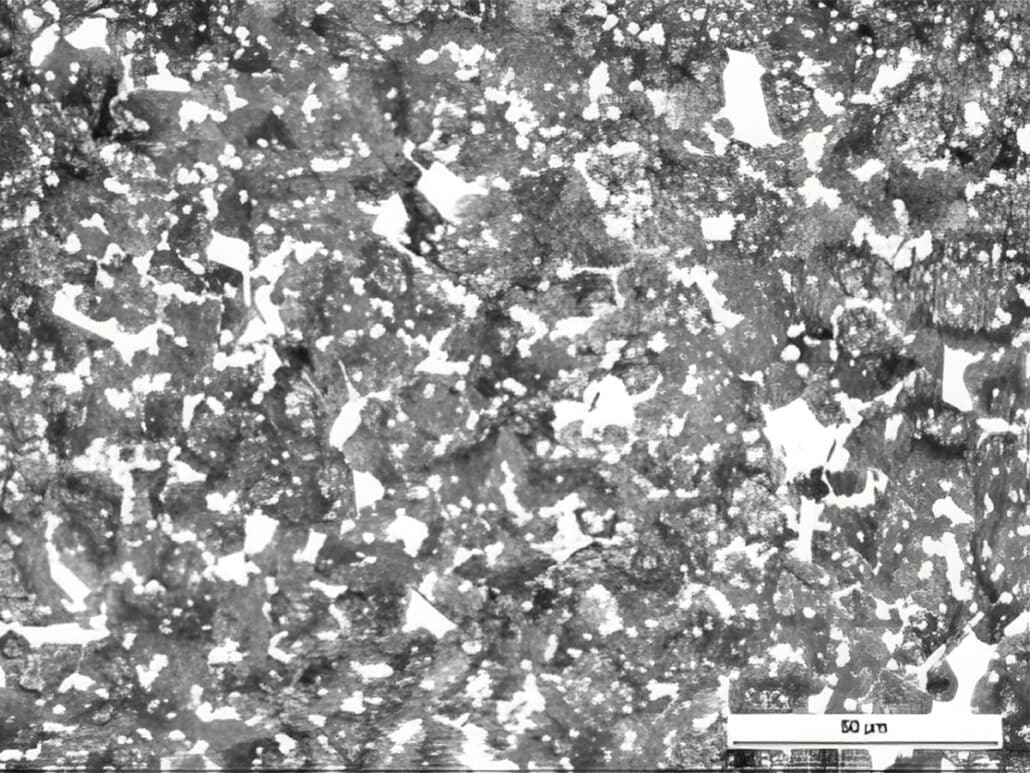

H11 has higher level of porosity than MIM 8620, it also has darker appearance in metallographic sections, due to its high carbon content and martensitic structure. The master alloy approach provide micro-structure of uneven porosity distribution and coarser grain size. MIM H11 with mater alloy approach can provide the highest hardness of 54HRC after sintering.

Sintered H11

Heat-treated H11

MIM H13

H13 Chemical Composition

| MIM H13 | Iron | Chromium | Molybdenum | Silicon | Vanadium | Carbon | Nickel | Copper | Manganese | Sulfur | Phosphorus |

| Percent by Weight | BaL. | 4.75-5.50 | 1.10-1.75 | 0.80-1.20 | 0.80-1.20 | 0.32-0.45 | 0.30 | 0.25 | 0.20-0.50 | 0.03 | 0.03 |

H13 Mechanical Properties

| Material | Density | Melting point | Tensile Strength | Yield Strength(0.2%) | Hardness | Thermal expansion (20-200 ℃) |

| MIM H11 | ≥7.80g/cm³ | 1427℃ | ≥1200Mpa | ≥900 Mpa | 53 HRC | 10.4x 10-6/℃ |

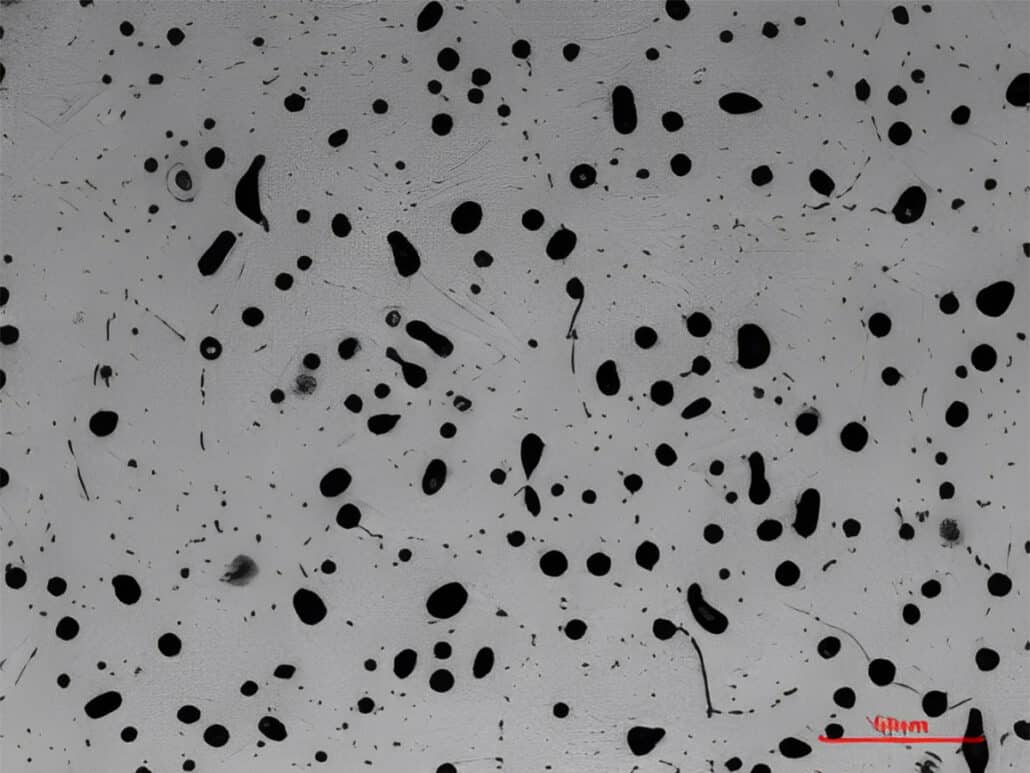

MIM H13 has similar micro-graph to H11, due to the basic chemistry and sintering density. In addition, H13 tool steel has similar properties to H11, but it has lower strength and hardness, even with a higher carbon level.

Sintered H13

Heat-treated H13

MIM S7

S7 Chemical Composition

| MIM S7 | Iron | Chromium | Molybdenum | Carbon | Vanadium | Manganese | Silicon | Copper | Sulfur | Phosphorus |

| Percent by Weight | BaL. | 3.00-3.50 | 1.30-1.80 | 0.45-0.55 | 0.20-0.30 | 0.20-0.80 | 0.20-1.00 | 0.25 | 0.03 | 0.03 |

S7 Mechanical Properties

| Material | Density | Tensile Strength | Yield Strength(0.2%) | Hardness | Thermal expansion (20-200 ℃) |

| MIM S7 | ≥7.83g/cm³ | ≥1300Mpa | ≥760Mpa | 41 HRC | 12.6x 10-6/℃ |

Although the micro-structure of MIM S7 resembles H13, its structure of bainite laths are more coarser than needle-like martensitic of H13. S7 has lower hardness than H13 but significant higher ductility after sintering.

Sintered S7

Heat-treated S7

MIM T15

T15 Chemical Composition

| MIM T15 | Iron | Tungsten | Cobalt | Vanadium | Chromium | Carbon | Molybdenum | Nickel | Copper | Manganese | Silicon |

| Percent by Weight | BaL. | 11.75-13.0 | 4.75-5.25 | 4.50-5.25 | 3.75-5.00 | 1.50-1.60 | 1.00 | 0.30 | 0.25 | 0.15-0.40 | 0.15-0.40 |

T15 Mechanical Properties

| Material | Density | Tensile Strength | Yield Strength(0.2%) | Hardness | Thermal expansion (20-200 ℃) | Thermal conductivity |

| MIM T15 | ≥8.19g/cm³ | ≥1280Mpa | ≥1090Mpa | 46.5 HRC | 9.9x 10-6/℃ | 20.9 x W/m-K |

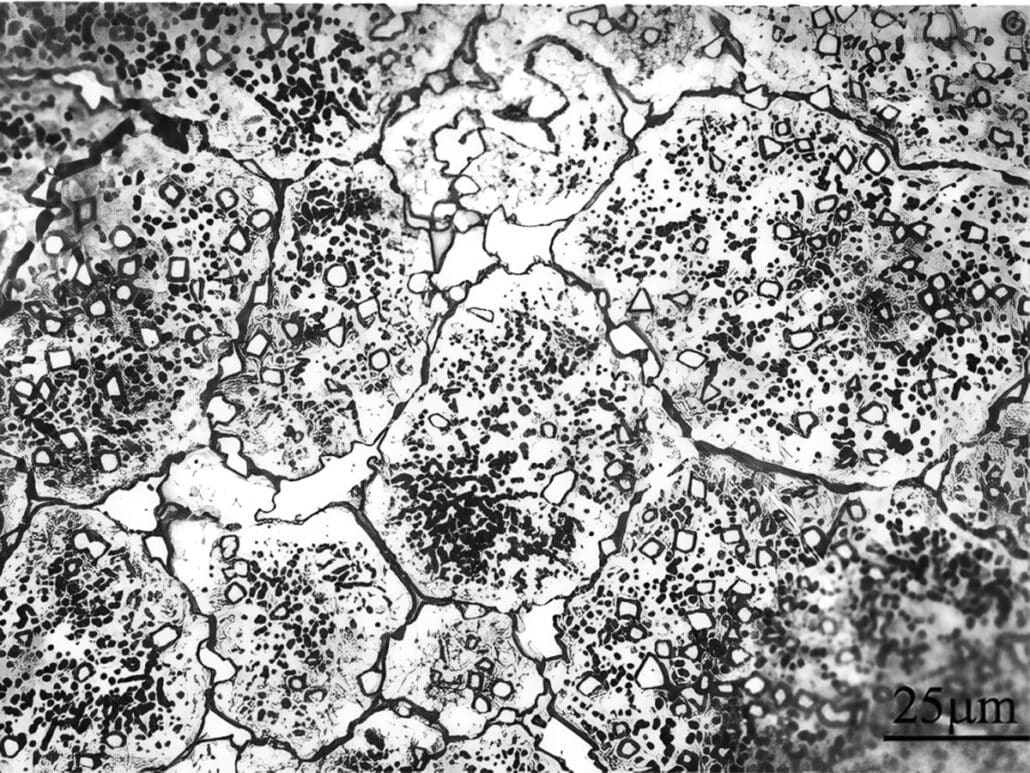

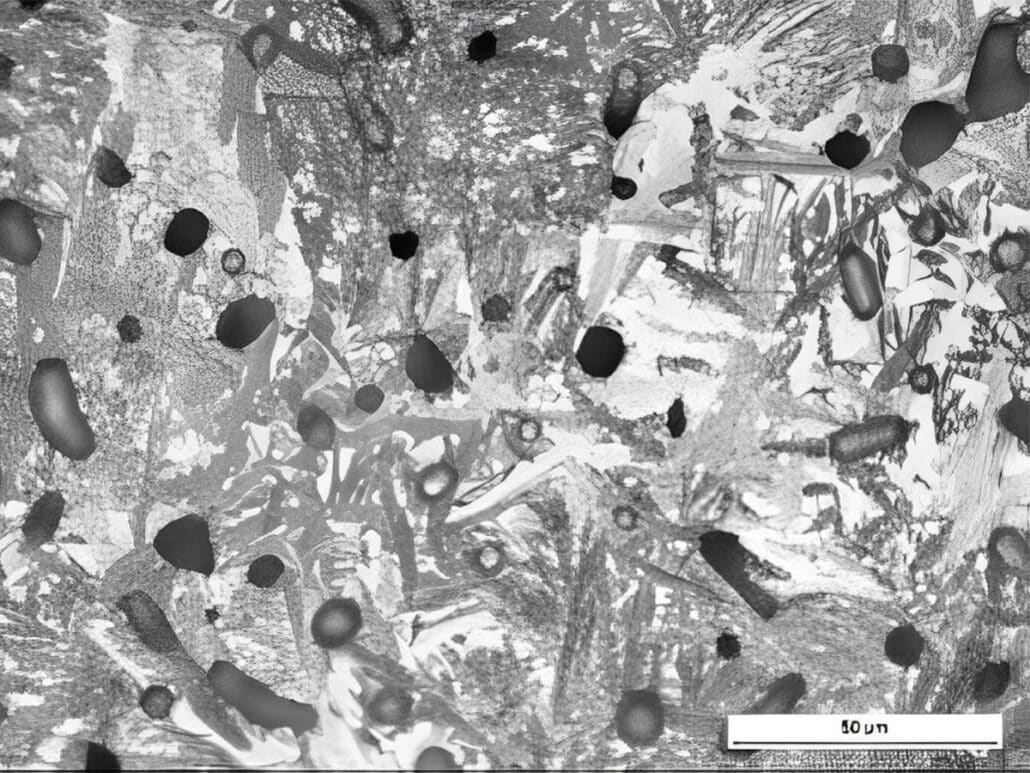

T15 can achieve the high density at sintering of 1240℃, the hardness value can reach to 65 HRC after optimized heat treatment. There is dramatic chemistry change in heat treatment of T15, the nitrogen content rise from 0.07% to 0.97% while carbon content decline from 1.52% to 0.79%.

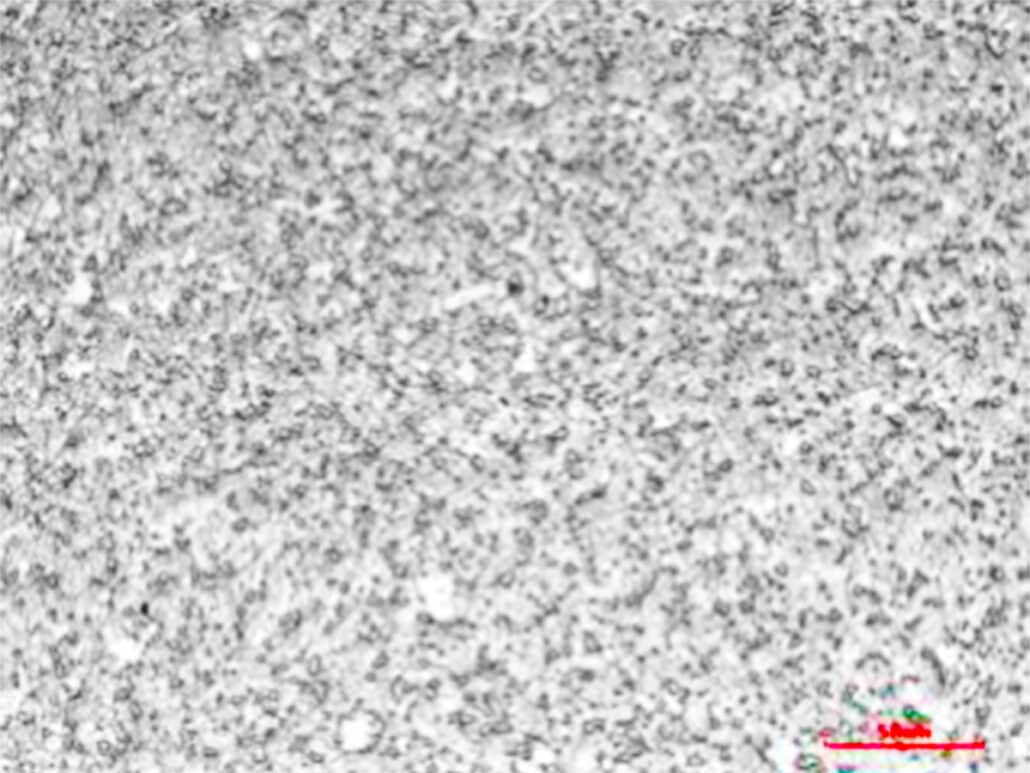

MIM T15 provide the uniform micro-structure of mixed carbides. In sintering process, T15 steel has far higher carbon loss than other tool steels, due to nitrogen displace carbon element in nitrogen sintering process. T15 provide the highest yield strength in tool steels with lighter low hardness.

Sintered T15

Heat-treated T15

Conclusion

Tool steels are new challenges in MIM technology. ZCMIM has more than 15 years of experience in different alloys of tool steel. We can apply different tooling steels in different projects. Contact us for your next MIM project of tool steels.