Soft Magnetic Materials

What are Soft Magnetic Materials?

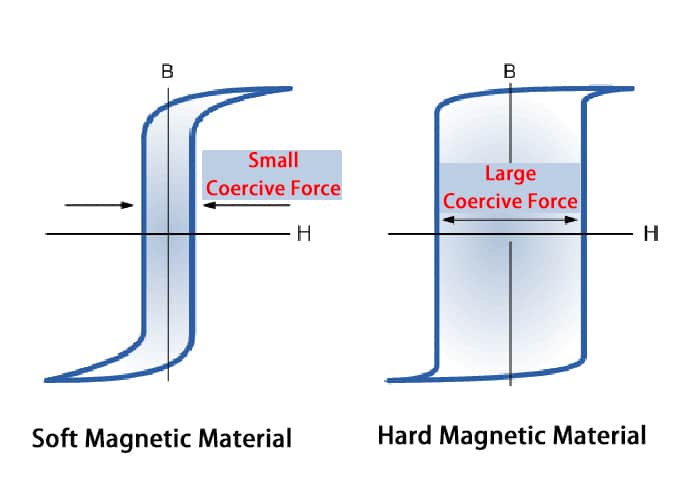

Soft magnetic materials are easily magnetized and demagnetized. These materials have intrinsic coercivity less than 1000 A/m. The main parameter is relative permeability, it measures the material’s responds to applied magnetic field. Other parameters including coerivity, saturation magnetization, electrical conductivity.

Soft-Hard Magnetic Material

There are two main categories of applications for soft magnetic materials: AC & DC. The high permeability is desirable for each application, while other properties are variable. For DC applications, material selection is depending on the permeability. Saturation magnetization is significant while in generation of magnetic field or creation of force. For AC applications, the most importation consideration is energy loss in hysteresis loop from three different sources: hysteresis loss, eddy current loss, anomalous loss.

In Metal Injection Molding manufacturing process, sintering of soft magnetic materials is a complex process. As a professional MIM manufacturer, we should notice the affection on properties and applications.

Properties of Soft Magnetic Materials

There are 5 main properties of soft magnetic materials:

Utmost permeability.

Slight coercive force.

Small hysteresis loss.

Small residual induction.

High saturation magnetization.

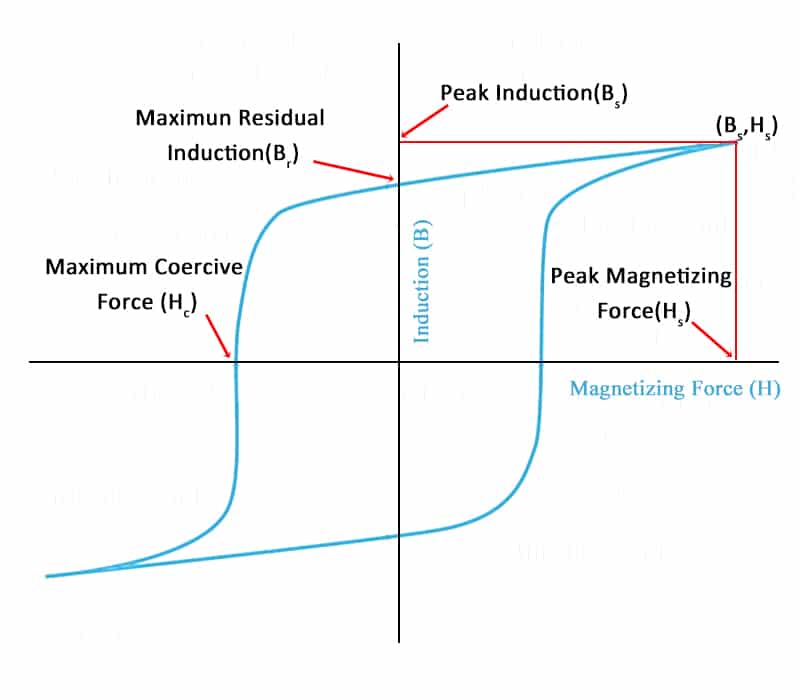

BH Loop

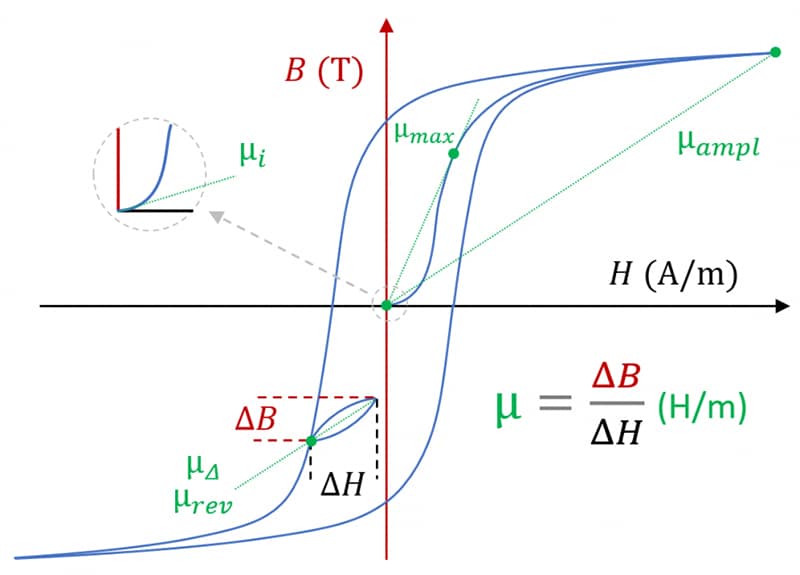

Permeability(μmax)

Magnetic permeability is a measurement of how can magnetize the materials. The high permeability implies that it is easy to achieve a certain level of magnetic induction, while with less applied field or less current. This reprrepresentsesent that the right soft magnetic material will save energy in actual applications.

(Note: The permeability is actually the instantaneous slope of the BH curve. The units are oersted / gauss; however, most science folks consider it a unitless number.)

Permeability

Coercive Force(Hc)

Coercive force is also called coercivity, this is a measure of how easy to demagnetize the material. It is the opposite of permeability. The lower the coercive force, the less current to get back zero induction.

(Note: Coercive force is measured in oersted or A/m [ampere per meter])

Maximum Induction(Bs)

This is the measure of induction at a given level of applied field, it is important to know the maximum induction once you require a specific level of induction or force. Maximum induction is a structure-sensitive property, the threshold for induction depends on the following characteristics:

- Material type

- Permeability

- Manufacturer sintering methods

- Sintering conditions

- Residual carbon and oxygen

- Post-processes or secondary operations.

Saturation Magnetization

The saturation magnetization is the measure of maximum filed that generate by the material. It depends on the dipole moment strength and package density of atoms. The atomic dipole moment is affected by the nature of atoms and the overall electronic structure in compounds. The package density is determined by the crystal structure and non-magnetic elements within the structure. For ferromagnetic materials, the saturation magnetization will depend on the relative moments alignment and the temperature.

Types of Soft Magnetic Materials

Iron-Silicone Alloys

Iron-silicone alloys are known as electrical steels, we normally apply these materials for transformer cores, electromagnet, electrical rotating machine. These materials are the most common soft magnetic material, the addition of silicon element will increase the permeability, reduce eddy current loss and hysteresis loss.

Amorphous & Nano-crystaline Alloys

These materials have extremely low coercivity, which is less than standard Fe-Si. This results in lower hysteresis losses. They have relatively low magnetization, and are not suitable for high current application. This kind of materials are specialized for low current applications and small devices. These alloys are single phase with relatively high resistivity, low anisotropy and good mechanical strength.

Nickel-Iron Alloys

Nickel-iron alloys are known as permalloy, these alloys have extremely versatile with a wide range of composition from 30% to 80%. Different composition give rise to the particular properties, such as: high Ni content with high permeability, 50% Ni content with high saturation magnetization, low Ni content with high electrical resistance. In addition, special grades Ni-Fe alloys have zero magnetostriction and zero magnetic anisotropy. Like Mu-metals, with a careful heat treatment and minor addition of Cu and Cr, have extremely high permeability to 300,000 and intrinsic coercivity of 0.4A/m.

Ceramic Magnets

Metallic soft magnetic materials are unable to apply in high frequency, because of the eddy current losses. Ceramic magnets are the most desirable material for ceramic insulators, the general composition is MO.Fe2O3, the M is a transition metal like nickel, manganese, or zinc.

MnZn ferrites are applied at high frequencies up to 10MHz, such as telephone signal transmitters and receivers, DC-AC converters in powder supplies.

Microwave ferrites are used in frequency from 100MHz to 500GHz, such as phase shifter in microwave devices.

Application of Soft Magnetic Materials

Soft magnetic materials have two sorts of applications, AC application and DC application.

DC (Direct Current) Application

In DC application, the materials are magnetized to carry out the operation, then demagnetized in the last part of the operation. The main consideration in material selection is permeability. We normally apply soft magnetic materials in the field of magnetic shielding, electromagnetic pole-pieces, solenoid switch. In addition, permanent magnet also apply these materials for flux line paths.

AC (Alternating Current) Application

In AC application, these materials are in magnetized state in whole operation time. This magnetization process is a continuous cycle from one direction to others. The energy loss is the main consideration for materials selection. This loss occurs in the hysteresis loop cycle, a good material has small energy loss. The main applications are power supply transformers, DC-AC converter, electric motors.

Magnetic Performance in Sintering

In metal injection molding manufacturing process, sintering temperature will affect final magnetic properties. Normally, iron-phosphorus and iron-silicone are two common power metal magnetic materials. In this case, sitnering temperature at 1120℃ will get iron-phosphorus benefit in final parts. However, sitnering temperature at 1260℃ can homogenize silicon element in ferro-silicon part.

Raise sintering temperature to required level will improve magnetic performance, by the following reasons:

- Alloy homogenization

- Reduction of oxides

- Greater sintering neck formation

- Material grain growth

- Increase of sintered density

MIM technology can satisfy the tailor performance in requirement, it is the preferred technology not only because of magnetic qualities, but also its complex-manufacturing capabilities. High density in MIM process relates to the maximum induction, such as the Fe50Co project.

Comparing to powder metallurgy technology, metal injection molding has higher density of 98% than 93% of powder metallurgy. This indicates that MIM parts have better magnetic performance than PM parts with same soft magnetic materials.

Soft Magnetic Materials in MIM

Metal injection molding applies sinter bonding to combine various metal powder together. High sintering temperature fuse the powder particles together, and create the necessary bonding. This sinter bonding process will not only create high density parts in requirements, but also bond two different pieces together.

Metal injection molding can produce more complex shapes than powder metallurgy. Its higher sintering temperature give rise to its unique advantages than other metalworking methods. MIM technology has its useful advantages in the following:

Unique Structure Capability

There are some unique structures cannot be molded once, we can separate one part into two pieces in two injection molding process. Then apply sinter bonding to assemble these two pieces together, such as the Incipio medical case.

Excellent Strength

Metal injection molding technology can create sintered part as strong as the original parts. These MIM parts have the same level of tensile and yield strength as traditional metalworking methods, such as: machining, stamping, casting.

No Additional Elements

There are no additional elements for sinter bonding in metal injection molding, we just need to rely on the unique qualities of the two part pieces. These two pieces can be the same materials, or two different materials.

Eliminate Secondary Process

We are able to create excellent MIM parts without secondary process. But this requires proper planning and execution from MIM designing to final finishing. As we eliminate more steps, the more cost-competitive to produce new parts.

Conclusion

ZCMIM provides different soft magnetic materials to satisfy various application in electronic and automotive industry. Our excellent knowledge and experience guarantee the final properties of soft magnetic materials in every project. Why not contact us for your next MIM project with these materials.