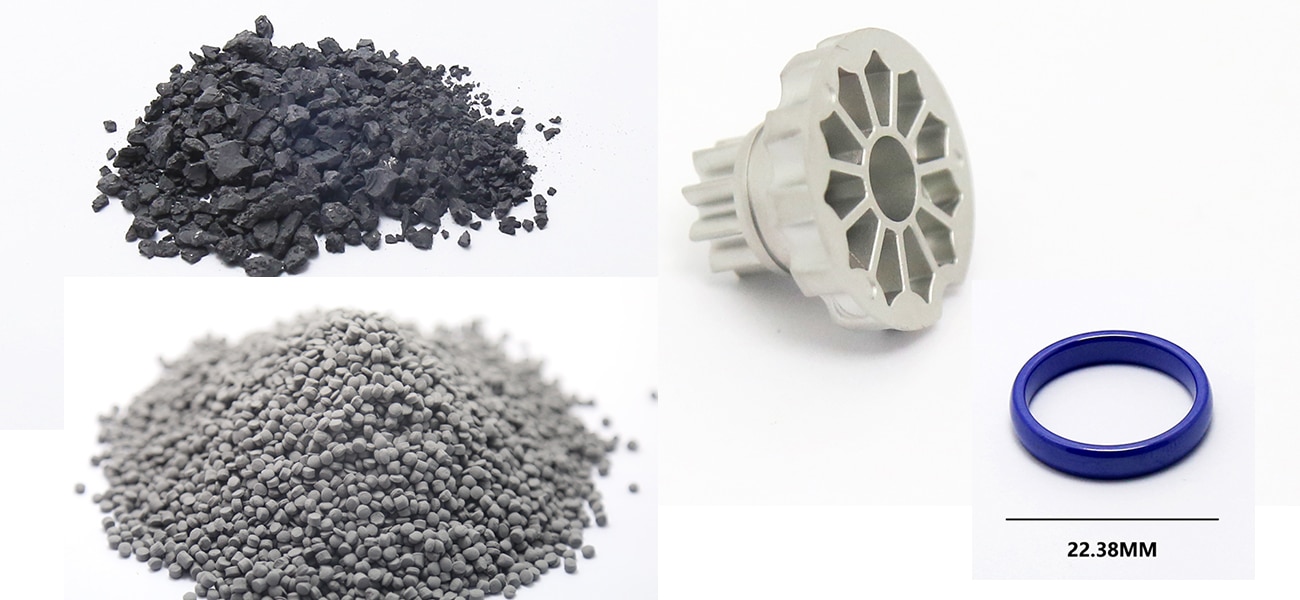

Metal Injection Molding Powder

Powder Injection Molding (PIM) is a cost-effective manufacturing technology for high volume production of shaped components from powders. According to the powder materials, PIM has two main types: metal injection molding (MIM) and ceramic injection molding (CIM). PIM technology is the ideal process to manufacture complex and functional parts with various material requirements in large quantities.

PIM combines the polymer injection molding technology with batch sintering process in powder metallurgy and ceramic processing. It is a cost-efficient mass production process for small and medium-size parts in range of 0.1 to 300 grams in weight. The main application of powder injection molding are precision apparatus equipment, medical industry, measurement and control technology, watch and household industry, weapon industry.

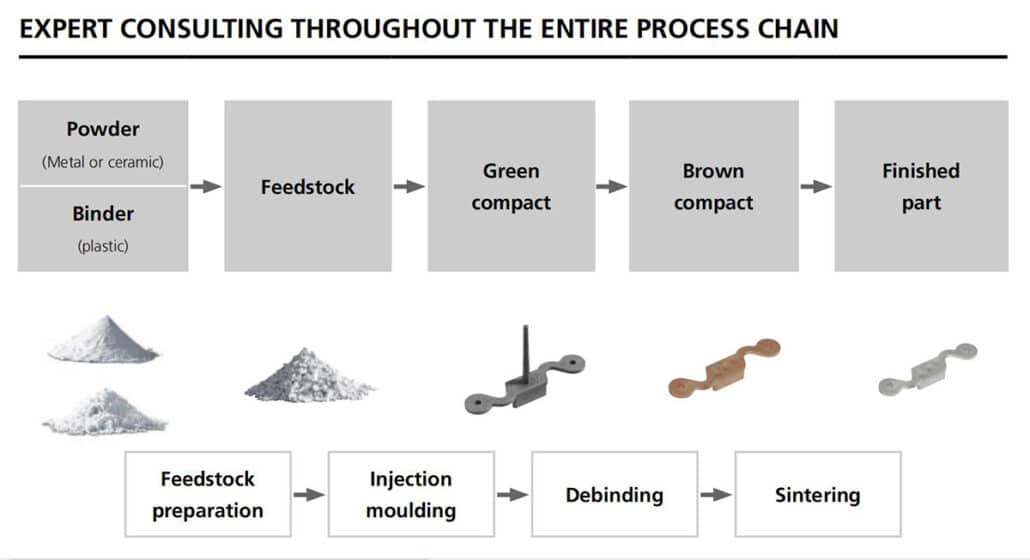

Power Injection Molding Process

Powder injection molding requires professional technology experience to ensure the final precision and quality. ZCMIM provides quality control across the whole process chain, from material preparation (feedstock) to the final post-processing.

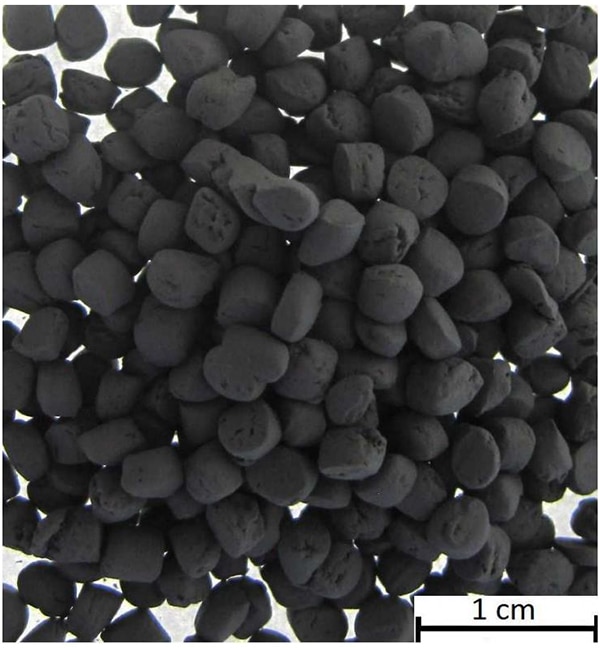

Powder Compounding

The powders in PIM are superfine metal or ceramic powders in dimension of 10-200 μm. These powders blend with plastic binder systems into an injection moldable compound (feedstock), then granulate into different sizes.

Injection Molding

The injection molding machine will inject the feedsotck (material compounds) into mold cavities. In this step, complex geometries are created. The PIM molded parts (both in MIM and CIM)are also known as green parts.

Debinding

Depending on different binder materials, the dissolution methods can be chemical or thermal. In debinding process, the binder in green parts are dissolved, then transform into brown parts.

Sintering

The brown parts are compressed in the sintering furnaces under a vacuum or shielding gas, the sintering temperatures range from 1300℃ (metal injection molding) to 1700℃ (ceramic injection molding). In the sintering process, metal or ceramic powders cohere together into net-shape density parts. In addition, depending on different materials, the brown parts have up to 30% volume reduction.

Post-processing

Powder injection molding (PIM) provides high surface quality and high dimension tolerance. For specific cases, additional operations are required to improve finishing or tolerance, such as polishing, grinding, shaping, PVD.

PIM Machine Equipment Highlights

For different sizes of metal and ceramic powders, there are different adapted machines are available, such as Micro-Powder, Smart-Powder, Eco-Powder.

- Micro-Powder: all electric micro injection molding machine with clamping force of 15 tons.

- Smart-Powder: servo-hydraulic injection machine with clamping force ranging from 25 to 400 tons.

- Eco-Powder: all electric and high-precise injection molding machine with clamping force ranging from 55 to 550 tons.

Regardless of different adapted machines, specific plasticizing units and mold components are still critical for smooth injection molding of MIM and CIM.

Wear-resistant Plasticizing Unit

Due to nearly 70% metal or ceramic powder contains in MIM or CIM feedstock, the plasticizing system should have specific strain from abrasion and adhesion. For injection molding process of PIM, all metaliferous components in plasticizing unit have special anti-wear features. Such as: bi-metallic barrels and screws made from abrasion-resistant steel alloy, special valve geometry to process molten PIM materials.

PIM Check Valve

As the check valves are exposed to abrasive strain particularly, these valves must be extremely wear-resistant, in order to adapt to the specific flow attributes of PIM feedstock. The precise geometry of the screw tip and shut-off ring is a fine compromise balance between large flow cross-section and repeatable closing behavior.

Longer Barrel Nozzle

Longer nozzles are available for the barrel, in order to minimize flow paths and pressure losses. Especially in multi-cavity mold processing, this will reduce the shot volume in production and the sprue scrap for recycling.

Mold-media Interfaces

MIM or CIM injection machine is adapted to the standard media requirements according to general experience. Optional extras including: additional cooling circuits, vacuum connections, the hydraulic core-pull system, electrical interfaces for limit switches and sensors.

Vacuum Pump

Vacuum pump can ensure the even filling of cavities without air pockets, it also results in better sealing at contact points, and minimize segregation of binder from powders.

Advantages of Powder Injection Molding

PIM has the common advantages as the following items:

- All metal alloys are possible, including alloy steels, stainless steels, nickel alloys, tungsten alloys, titanium alloys, copper alloys.

- A wide range of ceramic materials, including: oxide ceramics of aluminum oxide, zirconium oxide, non-oxide ceramics of nittrides, carbides or borides.

- PIM can produce complex geometries without additional mechanical finishing.

- PIM technology has high precision and repeatability in final parts.

- Power Injection Molding can achieve high quality surfaces without additional operations.

Powder Injection Molding provides attractive advantages for the unique metal or ceramic parts freedom of design, wide materials choice, cost-effective production for high-volume. Furthermore, our premium technology will extend the possible application ranges, such as: multi-component injection molding, dynamic mold temperature control. Our engineering team also has extensive expertise in different aspects:

- Versatile: individual custom metal or ceramic feedstocks for unique requirement.

- Precise: automatic removing and depositing process for high sensitive components.

- Innovative: biological and bio-compatible parts for medical and dental applications.

PIM Technology Application

Powder Injection Molding (PIM) technology provides great freedom to design high complex metal (MIM) or ceramic (CIM) parts. Its wide materials options result in wide applications:

Ceramic Micro Parts

Ceramic injection molding (CIM) is able to produce various micro components. Such as small parts of medical components, thermal and electrical insulation parts.

Ceramic mass-production

CIM technology can produce complex ceramic parts in reasonable cost saving, it is a competitive manufacturing method for grinders, cogwheels.

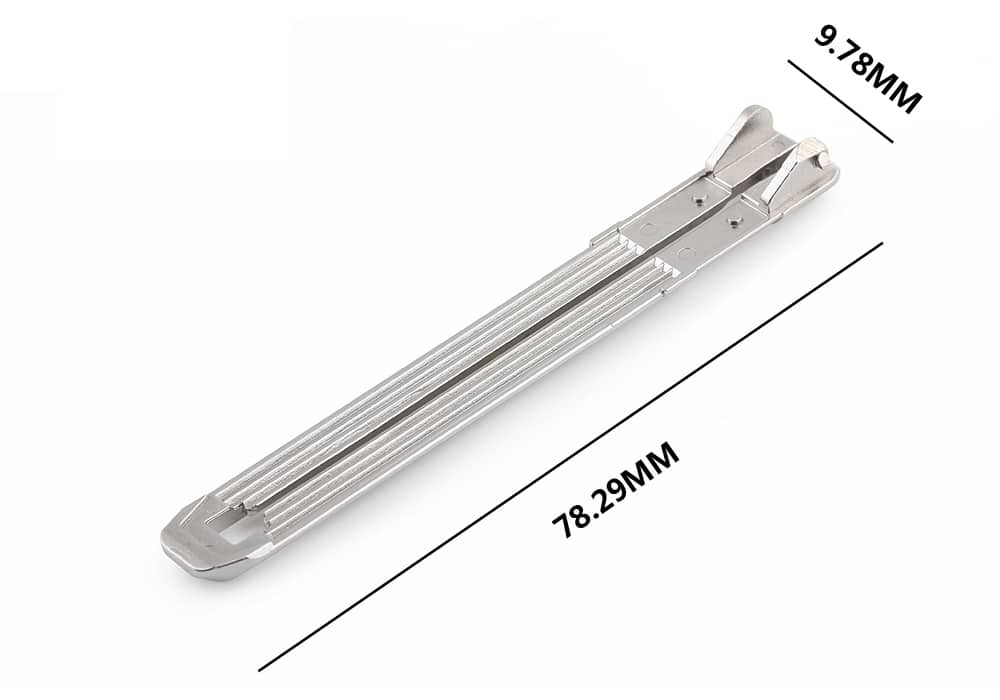

Micro MIM Parts

Metal injection molding (MIM) provides cost advantages for large batch production, especially for metal parts with micro dimensions. Comparing to CNC machining or additive manufacturing, MIM is an effective method for micro size metal parts.

Specific Tools

MIM is a effective method of tools production for machining. Especially the super alloys tools like: milling cutter, drills and cutting inserts.

High Precision Parts

Metal Injection molding is able to produce electric motors with high precision. All functional features are easy to produce without enormously expense.

High Technology Quality

High part quality is critical for powder injection molding, as defects in molded parts cannot eliminate by further debinding and sintering. In this case, we need to ensure the high quality of PIM (powder injection molding) in the following aspects.

- Reproducible basis: protective mold and high precise molding ensure reproducible mold filling without burr formation.

- Variety of expansions: our custom injection molding technology provides perfect solutions for various projects.

- Adapted plasticizing: PIM screws have low compression to prevent the overheating and decomposing of feedstock. Highly wear resistance of plasticizing components can protect against the abrasive powder-binder melt.