Metal Injection Molding vs Machining

Technology Process

Metal injection Molding (MIM)

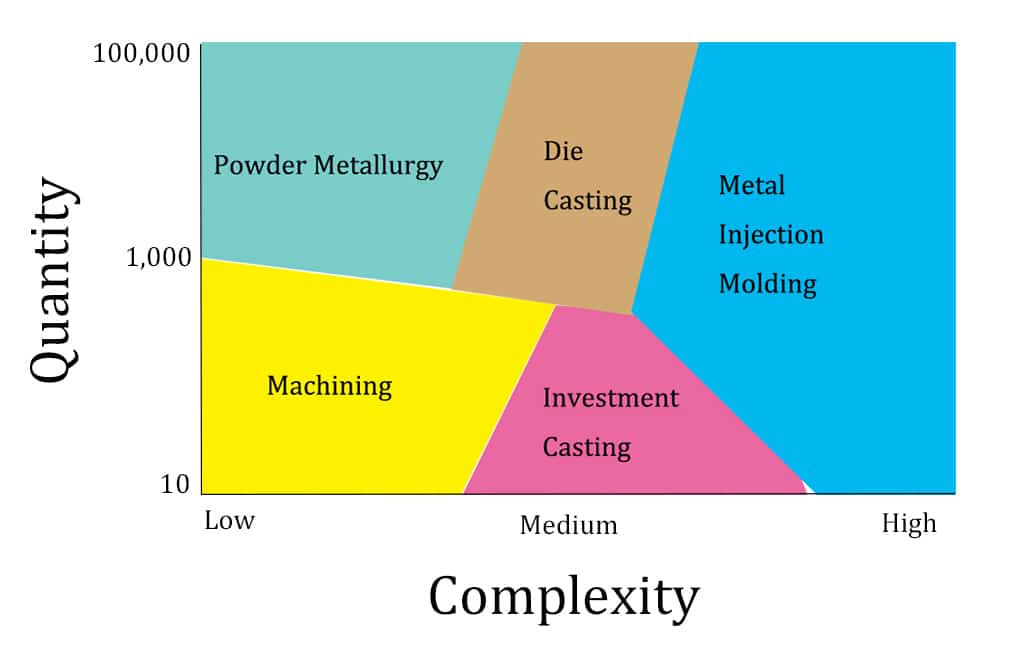

Metal injection molding (MIM) is an advanced metalworking technology, which combines two established injection molding and PM sintering technologies into the MIM manufacturing process. Therefore, it is most suitable for precise, complex metal parts with high volume quantities. There is nearly no limitation of MIM materials’ selection, any metal or alloys can be applied in MIM manufacturing process, while they are not capable for traditional metalworking methods like casting, machining. All in all, the most common metal injection molding materials are stainless steel and other low alloy steels.

If you are unfamiliar with the metal injection molding process, check our Metal Injection Molding web page.

Machining

Machining is a traditional metalworking method, its manufacturing process is removing unwanted metal material little by little from the raw workpieces, until achieving the final desired geometry. Machining is another alternative way to create parts which cannot be produced by die or investment casting. However, this method is not the most cost-effective solution for micro-size and complex components.

Difference in MIM vs Machining

In similarities, Metal Injection Molding is able to produce finished components with same mechanical properties as machined parts. Typically, MIM parts can be applied in the same area as machined parts, such as medical, electronic, industrial and automotive. In special cases, MIM parts has similar surface appearance as machined parts.

In the following table, we summarize the main properties of Metal Injection Molding (MIM) vs Machining:

| Parameters | Metal Injection Molding | Machining |

| Density | 94-98% | 100% |

| Surface Finish | High | High |

| Miniaturization | High | Low |

| Geometric Complexity | High | Medium |

| Design Flexibility | High | High |

| Thin Wall Capability | High | Low |

| Material Ranges | High | High |

| Production Quantity | High | Low-medium |

| Post-operation Feasibility | Good | Good |

| Dimensional Tolerance | High | High |

There are a few key differences between MIM vs Machining, all these elements will assist you to figure out the most suitable methods for your specific project requirements.

Unique Geometry

MIM can satisfy unique geometry and complexity capability requirement in any MIM parts. In addition, parts consolidation is widely used in MIM design process to produce one single part with desired features. By contrast, machining only can provide limited intricacy, design freedom and flexibility. It is difficult to produce complex structure, the cutting tools need sufficient working space for interior features. As we know, complex parts structures will need more machining time, which will no doubt increase total cost. While MIM is the most cost-effective way, its cost will never affect by parts geometries.

Strength and Performance

Although MIM and machining both can produce high strength metal parts with excellent mechanical properties. We should notice that MIM parts never need to endure induced stress or internal pressure in manufacturing process. For special design parts, these stresses and pressure in machining process will result in part deformation and failure. MIM parts are injection molded by conventional ways, then sintered in furnace, finally create a solid strong metal components. Therefore, MIM process will never create any stress or pressure to final parts.

Materials

Metal injection molding applies metal feedstock for injection molding process. Powdered metal feedstock is molded at high temperature and pressure to create small precision parts in large quantities. Therefore, it is suitable for small size metal components with sophisticated shapes and high precision. In addition, this technology provides high mechanical properties, strength, ductility, and magnetic response.

In reason of the flexibility of MIM technology, we also can customize MIM materials’ composition by customers specific attributes. Our common metal injection molding materials are stainless steels, low alloy steel, copper alloy, titanium alloy, nickel alloy, and tungsten alloys.

Part Size

MIM is ideal for high volume production of small and complex geometric metal parts. It can achieve 96% to 99% density, or 100% density after Hot Isostatic Press (HIP) treatment. Furthermore, it also has a significant lower cost than machined metal components.

Mold Investment

In MIM production process, the part complexity are always determining the final mold investment. Complex parts design requires indeed molds with complex insider cavities, in order to satisfy parts formation in injection molding process. Therefore, molding cost is an upfront cost before manufacturing process. Otherwise, with machining method, the main factor affect cost is process time, any complexity of parts will increase process time, and finally increase extra cost.

Material Scrap

In machining way, the removal of metal material from the block is obvious material scrap, and this is inevitable because of its manufacture way. However, MIM will never create any material scrap in process, so you can save cost in total.

Production Capacity

Machining needs long time to produce complex parts. Once you need high volume capacity, the only way is buying more CNC machines for more production. Otherwise, we have the most effective way to increase MIM capacity without any new machines purchase. Just need to plan our MIM parts production process in high volume production schedule.

Therefore, metal injection molding is suitable for automated production in large quantities with consistent quality. But machining is typically well-suited for lower production volumes with complex shapes and tighter tolerances. In normally, there are quite minimal finishing operations with MIM as less critical tolerances’ requirement in final applications. Although the initial investment of MIM molding is tremendous high, this cost is recovered quickly in high-volume production.

Tolerance

Metal injection molding has expected tolerances from ± 2 % to ± 0.4 %, all the final tolerances depend on detail feature size. In reason of shrinkage error in debinding and sintering, the larger features will result in the larger tolerances. As we know, the typical shrinkage in sintering process are from 15 % to 18 %. Non-isotropic is another factor affects the expected tolerance. Furthermore, gravity will cause more shrinkage on the vertical direction, while drag forces will result in less shrinkage on the lengthwise direction.

However, as machining has precise control on milling and turning tools, there are higher tolerances of final machined parts.

MIM vs Machining Manufacturing

Metal injection molding is ideal for complex metal parts with assembly requirement, especially for high-production of small precision components with intricate geometry. Therefore, MIM technology is the best option for economical miniature parts production. It provides more advantages and benefits for precision metal parts than machining technology. We summarize the common fabrication characteristics of MIM vs Machining is the following table.

| MIM Advantages | Machining |

| Complex geometry | Design limitations |

| High-automation process | Labor-intensive process |

| Lower cost | Costly process |

| No secondary operation requirement | Possible secondary machining steps |

| No material waste | Significant material waste |

| High-volume production | Low-volume production |

| Single tool molding | Multiple operations |

| Thin-wall features | Difficult for thin-walls |

| Exterior & Interior threads | Difficult for internal threads |

| Word & Numbers in molding | Unviable machining word & number |

Excellent Benefits of MIM

Compare to Machining, there are some additional benefits of MIM in manufacturing process.

High Repeatable

As machining produce parts in each separate process, every part has its own actual dimensions. Normally, these parts can reach normal accuracy. Once you need high tolerance requirement, it will encourage amount of manpower work to achieve. While in MIM, with multiple cavity technology, it is easy to control our MIM parts with high accuracy.

Cycle Time

In machining process, design complexity determine producing time, it will increase significantly with high complex geometries. While in MIM, there is little effect on complexity, MIM parts with same materials have similar cycle time, no matter how complex the parts are.

Part Consolidation

MIM technology can create parts with consolidation of various sections, which will simplify manufacturing process. In addition, there is no extra cost in budget and impact in performance.

Less Secondary Operations

As MIM parts’ surface roughness can reach 0.2 µm, and its properties are similar to raw material alloys. There is no need of secondary operations for functional parts.

Conclusion

MIM is the most cost-effective for precise applications compare with machining, especially in your high volume and complexity requirement projects. ZCMIM can produce high accuracy, complex geometries components with no post operation for your special applications. We also significantly reduce your associated cost in secondary operation ahead, while increase production rate.