Electronic MIM Parts

MIM Watch Parts Gallery

MIM technology is widely used in watch parts production, no matter internal function parts or external watch case and strap. ZCMIM provides high precision watch case and strap with excellent strength properties. Further post-operations as PVD coating, polishing, grinding will be used to improve surface appearance.

Watch Case

- Material: Stainless steel 316L

- Size: 37.84mm×42.04mm

- Density: ≥7.8g/cm³

- Properties: Tensile strength of 510 MPa, Yield strength≥180 MPa, Hardness of 120HV10.

- Manufacturing process: Metal injection molding, Magnetic grinding,Polishing, PVD coating.

- Material: Stainless steel 316L

- Size: 37.81mm×41.89mm

- Density: ≥7.8g/cm³

- Properties: Tensile strength of 510 MPa, Yield strength≥180 MPa, Hardness of 120HV10.

- Manufacturing process: Metal injection molding, Magnetic grinding, Sandblasting, PVD coating.

- Material: Stainless steel 316L

- Size: 39.64mm×52.86mm

- Density: ≥7.8g/cm³

- Properties: Tensile strength of 510 MPa, Yield strength≥180 MPa, Hardness of 120HV10.

- Manufacturing process: Metal injection molding, Magnetic grinding, Polishing, PVD coating.

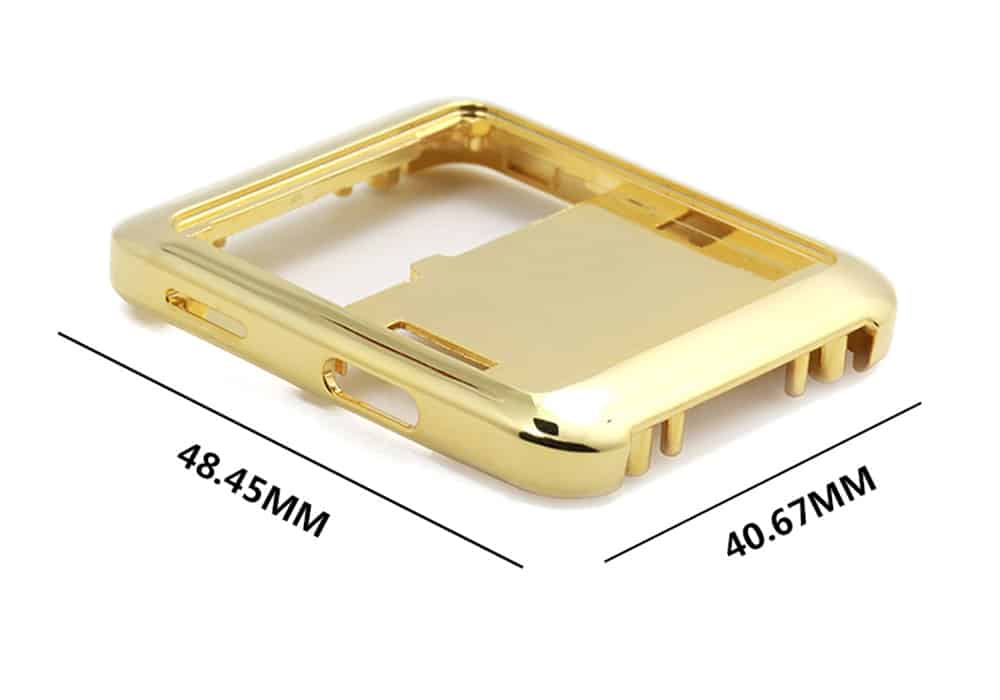

- Material: Stainless steel 316L

- Size: 40.67mm×48.45mm

- Density: ≥7.8g/cm³

- Properties: Tensile strength of 510 MPa, Yield strength≥180 MPa, Hardness of 120HV10.

- Manufacturing process: Metal injection molding, Magnetic grinding, Polishing, PVD coating.

- Material: Stainless steel 316L

- Size: 46.14mm diameter

- Density: ≥7.8g/cm³

- Properties: Tensile strength of 510 MPa, Yield strength≥180 MPa, Hardness of 120HV10.

- Manufacturing process: Metal injection molding, Magnetic grinding.

- Material: Stainless steel 316L

- Size: 44.79mm×56.00mm

- Density: ≥7.8g/cm³

- Properties: Tensile strength of 510 MPa, Yield strength≥180 MPa, Hardness of 120HV10.

- Manufacturing process: Metal injection molding, Magnetic grinding.

- Material: Stainless steel 316L

- Size: 42.79mm×22.35mm

- Density: ≥7.8g/cm³

- Properties: Tensile strength of 510 MPa, Yield strength≥180 MPa, Hardness of 120HV10.

- Manufacturing process: Metal injection molding, Magnetic grinding, Polishing, PVD coating.

- Material: Stainless steel 316L

- Size: 33.73mm diameter

- Density: ≥7.8g/cm³

- Properties: Tensile strength of 510 MPa, Yield strength≥180 MPa, Hardness of 120HV10.

- Manufacturing process: Metal injection molding, Magnetic grinding.

MIM parts with excellent mechanical properties are perfect for watch and smart-wear applications. Multiple post-processing technologies like grinding, PVD coating or polishing can improve final parts appearance performance, in order to satisfy aesthetic and functional requirements.

Watch Strap

- Material: Stainless steel 316L

- Size: 23.7mm×40.15mm

- Density: ≥7.8g/cm³

- Properties: Tensile strength of 510 MPa, Yield strength≥180 MPa, Hardness of 120HV10.

- Manufacturing process: Metal injection molding, Magnetic grinding, Polishing, Sandblasting.

- Material: Stainless steel 316L

- Size: 25.41mm×49.36mm

- Density: ≥7.8g/cm³

- Properties: Tensile strength of 510 MPa, Yield strength≥180 MPa, Hardness of 120HV10.

- Manufacturing process: Metal injection molding, Magnetic grinding, Polishing, PVD coating.

- Material: Stainless steel 316L

- Size: 21.35mm×37.91mm

- Density: ≥7.8g/cm³

- Properties: Tensile strength of 510 MPa, Yield strength≥180 MPa, Hardness of 120HV10.

- Manufacturing process: Metal injection molding, Magnetic grinding, Polishing, PVD coating.

- Material: Stainless steel 316L

- Size: 21.35mm×37.91mm

- Density: ≥7.8g/cm³

- Properties: Tensile strength of 510 MPa, Yield strength≥180 MPa, Hardness of 120HV10.

- Manufacturing process: Metal injection molding, Magnetic grinding, Polishing, PVD coating.

Watch Assemble Parts

- Material: Stainless steel 316L

- Size: 26.53mm×7.45mm

- Density: ≥7.8g/cm³

- Properties: Tensile strength of 510 MPa, Yield strength≥180 MPa, Hardness of 120HV10.

- Manufacturing process: Metal injection molding, Magnetic grinding.

- Material: Stainless steel 316L

- Size: 9.3mm×32.0mm

- Density: ≥7.8g/cm³

- Properties: Tensile strength of 510 MPa, Yield strength≥180 MPa, Hardness of 120HV10.

- Manufacturing process: Metal injection molding, Magnetic grinding, PVD coating.

- Material: Stainless steel 316L

- Size: 25.25mm×29.4mm

- Density: ≥7.8g/cm³

- Properties: Tensile strength of 510 MPa, Yield strength≥180 MPa, Hardness of 120HV10.

- Manufacturing process: Metal injection molding, Magnetic grinding.

- Material: Stainless steel 316L

- Size: 6.9mm×10.2mm

- Density: ≥7.8g/cm³

- Properties: Tensile strength of 510 MPa, Yield strength≥180 MPa, Hardness of 120HV10.

- Manufacturing process: Metal injection molding, Magnetic grinding.

- Material: Stainless steel 316L

- Size: 9.57mm×67.21mm

- Density: ≥7.8g/cm³

- Properties: Tensile strength of 510 MPa, Yield strength≥180 MPa, Hardness of 120HV10.

- Manufacturing process: Metal injection molding, Magnetic grinding.

- Material: Stainless steel 316L

- Size: 21.00mm×10.96mm

- Density: ≥7.8g/cm³

- Properties: Tensile strength of 510 MPa, Yield strength≥180 MPa, Hardness of 120HV10.

- Manufacturing process: Metal injection molding, Magnetic grinding.

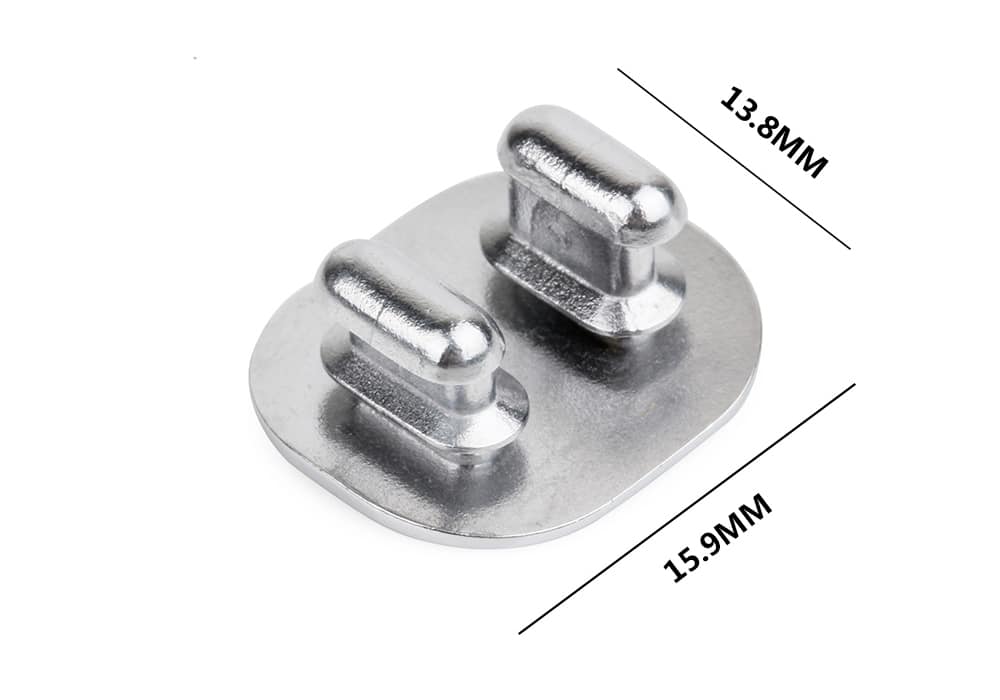

- Material: Stainless steel 316L

- Size: 13.8mm×15.9mm

- Density: ≥7.8g/cm³

- Properties: Tensile strength of 510 MPa, Yield strength≥180 MPa, Hardness of 120HV10.

- Manufacturing process: Metal injection molding, Magnetic grinding.

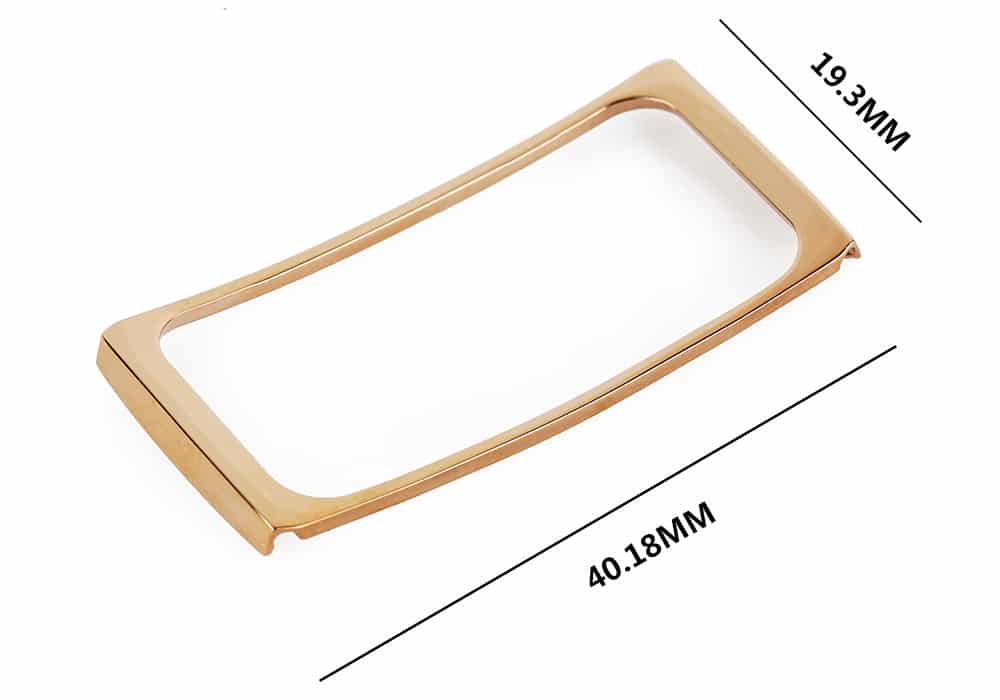

- Material: Stainless steel 316L

- Size: 19.30mm×40.18mm

- Density: ≥7.8g/cm³

- Properties: Tensile strength of 510 MPa, Yield strength≥180 MPa, Hardness of 120HV10.

- Manufacturing process: Metal injection molding, Magnetic grinding, PVD coating.

- Material: Stainless steel 316L

- Size: 12.45mm×7.43mm

- Density: ≥7.8g/cm³

- Properties: Tensile strength of 510 MPa, Yield strength≥180 MPa, Hardness of 120HV10.

- Manufacturing process: Metal injection molding, Magnetic grinding.

- Material: Stainless steel 316L

- Size: 7.39mm×3.78mm

- Density: ≥7.8g/cm³

- Properties: Tensile strength of 510 MPa, Yield strength≥180 MPa, Hardness of 120HV10.

- Manufacturing process: Metal injection molding, Magnetic grinding, PVD coating.

ZCMIM had cooperated with Kinetron to produce functional Base Plate parts for their new smart-wear development. Our high tolerance and accuracy guarantee the further assembly process.