Metal Injection Molding Materials

MIM Materials

Common MIM Materials

Metal Injection Molding produces various high-performance, complex-geometries parts without additional machining. In reason of MIM parts high density, its properties are equivalent to other fabrication method. There is high flexibility of material selection, same equipment can be produced by different metal materials. Furthermore, wide varieties of metal can be applied in MIM process. Metal powder with various chemical composition, particle sizes and shapes will determine final MIM parts properties. All in all, Our MIM materials are classified into categories as following:

Ferrous alloys: steel, stainless steel, tool steel, low alloy steel, iron-nickel alloy, special ferrous alloys like Invar and Kovar.

Tungsten alloys: tungsten-copper, tungsten heavy alloys.

Nickel alloys: nickel, nickel-base superalloys.

Molybdenum alloys: molybdenum, molybdenum-copper.

Titanium alloys: titanium, titanium alloys.

Hard materials: cobalt-chromium, cemented carbides(WC-Co), cermet(Fe-TiC).

Specific materials: aluminum, precious metal, copper and copper alloys, cobalt-based alloys, magnetic alloys (soft and hard), shape-memory alloys.

Stainless steel

Low steel alloy

Specific alloy

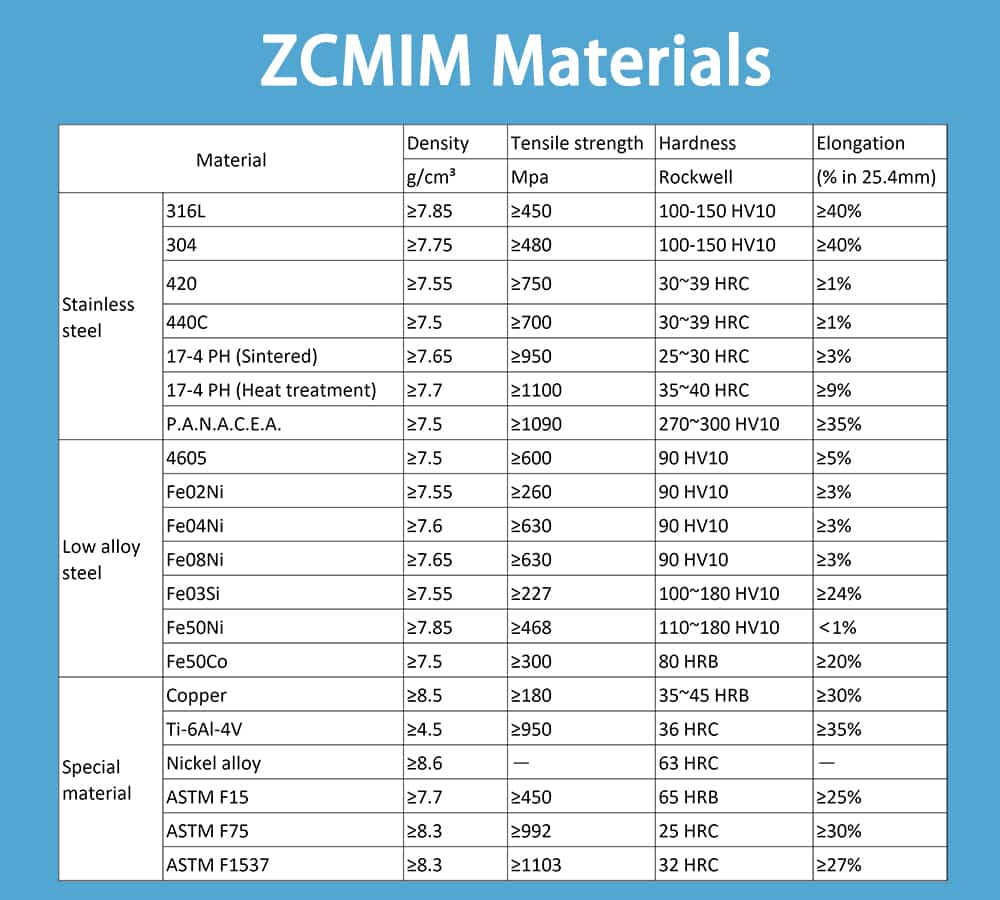

ZCMIM Materials

You can check our common MIM materials as following graph.

Custom MIM Materials

Most alloys composition are copied from standard handbook formulations. However, it cannot be ignored that long-term anneal in sintering process will degrade alloy properties, since most alloys were created and developed in casting technology. So, ZCMIM utilize modified chemistry way in MIM technology, in order to guarantee the physical and chemical properties of MIM parts.

Such as 316L alloy composition (Fe-19Cr-9NI-2Mo) is wildly applied in reason of its corrosion resistance and combined strength properties. Otherwise, extra additional chromium in alloy composition will make sintering process easily, so this alloy provide attainable superior properties with this alternative metal manufacturing method.

Custom metal powder can be fabricated with additional cost once composition is unavailable. There is no doubt that ZCMIM will satisfy your any custom material requirement in most cost-effective price.

MIM Material Options

MIM Material Applications

We need to consider many factors to select perfect material for MIM parts, such as MIM parts weight, tolerance requirement, mechanical stress, hardness, additional machining, maximum cross-section, corrosion resistance, etc.

| Material Category | Material Type | Characteristics | Application |

| Stainless steel | 316L | Corrosion resistance | Horology parts, electronic component |

| Stainless steel | 304 | High strength | Electronic parts, micro-gears |

| Stainless steel | 420 | High strength | Pneumatic machinery, cutlery, tools |

| Stainless steel | 440C | Friction resistance, corrosion resistance | Hand tools, sporting equipment |

| Stainless steel | 17-4 PH | Corrosion resistance and strength | Medical, dental, surgical parts |

| Stainless steel | P.A.N.A.C.E.A | Non-magnetic | Electronics, |

| Fe-based alloy | 4605 | Exceptional strength, good ductility | Consumer products, hand tools |

| Fe-based alloy | Fe3%Si | High electrical resistance | Electrical parts |

| Fe-based alloy | Fe50%Ni | High permeability | Electrical parts |

| Fe-based alloy | Fe50Co | High permeability | Micro-motor |

| Copper | Copper alloy | Thermal & electrical conductivity | Heat conduction, electric conduction |

| Hard alloy | Nickel alloy | electrical conductivity, corrosion resistance | Electrical parts, wristwatch parts |

| Titanium | Ti-6Al-4V | Corrosion resistance, light weight | Medical parts |

| Special alloy | ASTM F15 (Kovar) | Controlled expansion | Splitter, micro-electronic parts |

| Special alloy | ASTM F75 | Bio-compatibility, wear resistance | Medical, orthopedics, dental parts |

| Special alloy | ASTM F1537 | Bio-compatibility, corrosion resistance | Medical parts |

ZCMIM provides common MIM materials for different application as following: Click here to check our detail MIM material properties.

Typical Material Properties

For custom MIM parts requirement, we also offer you mechanical properties of typical MIM materials as following table:

| Metal Type | MIM model | Density | Tensile strength | Hardness | Elongation |

| Iron Base | Secondary treatment | g/cm³ | Mpa | Rockwell | (% in 25.4 mm) |

| Stainless steel | 316L | 7.8 | 515 | 67HRB | 50 |

| Stainless steel | 304 | 7.8 | 515 | 63HRB | 50 |

| Stainless steel | 420 | 7.7 | 1737 | 45HRC | 3.5 |

| Stainless steel | 440C | 7.6 | 1655 | 49HRC | 1 |

| Stainless steel | 17-4 PH (sintered) | 7.5 | 896 | 27HRC | 6 |

| Stainless steel | 17-4 PH (Heat treatment) | 7.5 | 1186 | 33HRC | 6 |

| Stainless steel | 17-4 PH(H900) | 7.7 | 1206 | 40HRC | 9 |

| Stainless steel | 17-4 PH(H1100) | 7.7 | 1000 | 34HRC | 12 |

| Stainless steel | P.A.N.A.C.E.A | 7.5 | 1090 | 300HV10 | 35 |

| Low alloy steel | 4605 (sintered) | 7.5 | 440 | 48HRB | 15 |

| Low alloy steel | 4605 Low hardness | 7.5 | 1151 | 36HRC | 3 |

| Low alloy steel | 4605 High hardness | 7.5 | 1655 | 48HRC | 2 |

| Low alloy steel | Fe3%Si | 7.6 | 227 | 80HRB | 24 |

| Low alloy steel | Fe50%Ni | 7.8 | 468 | 50HRB | 30 |

| Low alloy steel | Fe50Co | 7.95 | 300 | 80HRB | 1 |

| Specific alloy | Copper alloy | 8.5 | 165 | — | 30 |

| Specific alloy | Titanium alloy | 4.5 | 950 | 36HRC | 18 |

| Specific alloy | Nickel alloy | 8.6 | — | 53HRC | — |

| Specific alloy | ASTM F15 (Kovar) | 7.7 | 450 | 65HRB | 25 |

| Specific alloy | ASTM F75 | 8.3 | 992 | 25HRC | 30 |

| Specific alloy | ASTM F1537 | 8.3 | 1103 | 32HRC | 27 |

Start Your MIM Project Now

MIM Material Properties

MIM products are sintered to approximately 98% density below theoretical, so its chemical, physical, elastic and thermodynamic will be affected by MIM sintering process compare to handbooks information.

ZCMIM aim to provide high quality MIM parts for our customers, so we consider materials affection in MIM sintering process. It will assist our engineering team offer multiple treatment suggestion for your projects.

Mechanical Properties

MIM technology products have same tensile match other manufacturing routes.

Fatigue Strength and Fracture Toughness

For high toughness metal materials, we never need to worry about this issue. But in other case, materials testing is recommended, because of large grain size and residual porosity associated with MIM.

Corrosion Resistance

Stainless steel with MIM method will cause corrosion resistance issue, in reason of chromium preferential surface evaporation during sintering process will degrade resistance to corrosion attack. But, with proper post-sintering and surface treatment, final MIM parts can perform well in general corrosion resistance of various media.

Bio-compatibility

MIM parts are applied more and more in medical and dental area, so biocompatibility become equivalent to other routes. In that case, post-sintering and electrochemical treatment are required to re-uniform MIM parts surface chemistry for biocompatibility.

Wearing Performance

In MIM process, mix hard phases into feedstock will improve MIM parts wearing behavior. Such as, MIM tool steel treated with low concentration calcium difluoride has significant dry wear rate than wrought tool steel. Add titanium nitride or chromium boride to stainless steel will improve final product wear resistance.

ZCMIM is able to satisfy The Metal Powder Industries Federation (MPIF) issues standards: MPIF Standard 35, Materials Standards for Metal Injection Molded Parts—2018 Edition. This is the most comprehensive standard of encompassing all facets in Metal Injection Molding Industry.