Metal Injection Molding

Metal Injection Molding

Metal injection molding, also known as MIM, is an advanced metal manufacturing process, which is a cost-effective metal parts production method with high density, complex geometries and excellent properties. As a new invention of MIM manufacturing, it combines flexibility of injection molding with strong structural integrity of powder metal sintering. The strength, economy and capacity for complex geometrical metal parts demonstrated in metal injection molding are sought-after attributes for customers. These MIM advantages promote its wide application in Electronic, Medical, Industrial, Automotive industries.

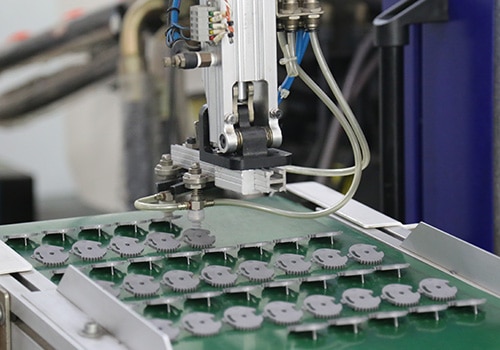

MIM Process

Metal Injection Molding is a metal parts manufacturing process for complex structure with high precision. This molding process combines metal powder, injection molding and sintering technologies together, in order to guarantee MIM parts can be complex with tight tolerance as well as excellent surfaces. In addition, select metal powder with various size and shape and complement additives will create different MIM parts chemical and physical properties, binder component for every powder particle will determine final form rigidity.

ZCMIM team will cooperate with you to assess the feasibility for MIM production cost, material and manufacturing. We will also give our suggestion of design adjustment to achieve the best effect of Metal Injection Molding.

Our main step of MIM including: Compounding, Injection molding, Debinding, Sintering.

MIM Advantages

Metal Injection Molding (MIM) has several advantages over traditional metal production technologies. As 30 years continuous development of MIM technology, ZCMIM can apply this technology producing MIM parts with high volume, various alloys, different size and complex structure. Our summary of MIM advantages as following:

Design Complexity

This technology can produce more complex parts than other metal forming methods. You can freely add cross holes, angel holes, splines, undercuts, side holes and groove in your parts design without any limitation. In addition, MIM can create whole parts without separate producing and assembly of post-production production way.

Excellent Properties

It can produce fully dense metal parts close to theoretical sintering density in a complete process, so MIM parts’ physical and chemical performance is excellent. MIM parts’ mechanical strength is significant beyond powder metallurgy, in addition, it can be produced by MIM but never machined out of bar stock.

Small Size

MIM technology uses very fine metal powder to produce high density metal parts, it is most suitable for small parts manufacturing, typically weight between 0.1 and 250 grams. All these parts are difficult and arduous to manufacture by traditional ways.

Environment Economical

This technology always use suitable amount of metal materials to create determined quantity of MIM parts. There is no material waste compare to machining process, raw material utility will be close to 100% and effectively avoid waste of materials.

Powerful Capacity

MIM is the most cost-effective metal parts manufacturing process, its production capacity can be adjusted flexibly from hundreds to millions per day.

High Tolerance

Sintering in MIM can achieve high tolerance of ±0.5% on dimension and ±0.3% on target. Combine MIM with other processing methods, it will increase to higher dimensional accuracy.

Flexible Materials

Metal injection molding technology can be applied for most of metal materials, consider of metal special properties and economic perspective, our main applied materials including:iron, steel, nickel, copper, titanium and alloy.

Delicate Appearance

Sintering surface toughness can achieve 1μm, it is perfect for further surface treatment, and get excellent dazzling appearance.

Various Application

MIM technology can satisfy various application in different industries. Its high quality ensures its wide application in environment with corrosion resistance, high strength and tolerance.

Start Your MIM Project Now

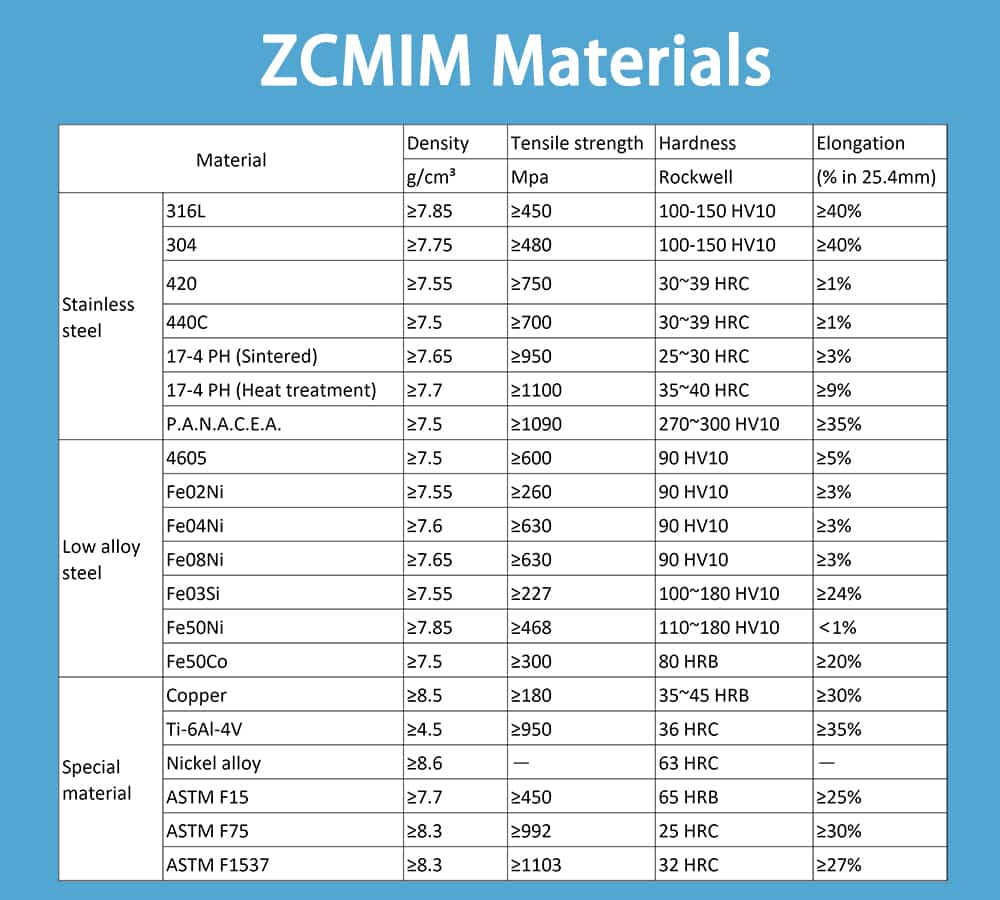

MIM Materials

A wide variety of metal materials can be applied in MIM process. Metal powder with various chemical composition, particle sizes and shapes will determine final MIM parts properties. ZCMIM main MIM metal materials are classified into categories as following:

Ferrous alloys: steel, stainless steel, tool steel, low alloy steel, iron-nickel alloy, special ferrous alloys like Invar and Kovar.

Tungsten alloys: tungsten-copper, tungsten heavy alloys.

Nickel alloys: nickel, nickel-base superalloys.

Molybdenum alloys: molybdenum, molybdenum-copper.

Titanium alloys: titanium, titanium alloys

Hard materials: cobalt-chromium, cemented carbides(WC-Co), cermets(Fe-TiC)

Special materials: aluminum, precious metal, copper and copper alloys, cobalt-based alloys, magnetic alloys (soft and hard), shape-memory alloys

Most alloys composition are copied from standard handbook formulations, but it cannot be ignored that long-term anneal in sintering process will degrade alloy properties, since most alloys were created and developed in casting technology. So ZCMIM utilize modified chemistry in way to MIM technology, in order to guarantee MIM parts’ physical and chemical properties.

Such as 316L alloy composition (Fe-19Cr-9NI-2Mo) is wildly applied in reason of its corrosion resistance and combined strength properties. Extra additional chromium in alloy composition will make sintering process easily, so this alloy provides attainable superior properties with this alternative metal manufacturing method.

Custom metal powder can be fabricated with additional cost once composition is unavailable. There is no doubt that ZCMIM will satisfy your any custom material requirement in most cost-effective price.

MIM Tolerance

Our MIM (Metal Injection Molding) part tolerance is ±0.3%-0.5% nominally, in special accuracy requirement, we can provide tighter tolerance with our high quality management if deemed essential.

As MIM component production is normally over a wide range, it is difficult to address tolerance directly. ZCMIM create a list of tolerance versus size in MIM parts manufacturing as following

| ± 0.03 mm for features below 3 mm |

| ± 0.05 mm for features between 3 and 6 mm |

| ± 0.08 mm for features between 6 and 15 mm |

| ± 0.15 mm for features between 15 and 30 mm |

| ± 0.25 mm for features between 30 and 60 mm |

In addition, for various feature in MIM parts, ZCMIM also provide a tolerance list for customer reference:

| Feature | Nominal or Typical ± | Best possible ± |

| Absolute dimension | 0.025 mm | 0.05 mm |

| Angle | 0.05° | 2° |

| Density | 0.2% | 1% |

| Dimension | 0.05% | 0.3% |

| Flatness | 0.1% | 0.2% |

| Hole diameter | 0.04% | 0.1% |

| Hole location | 0.1% | 0.3% |

| Parallelism | 0.2% | 0.3% |

| Perpendicularity | 0.1% or 0.1° | 0.2% or 0.3° |

| Roundness | 0.3% | 0.3% |

| Surface roughness | 0.2 µm | 0.8 µm |

| Weight | 0.1% | 0.4% |

| Corner radius | 0.1 mm | 0.15 mm |

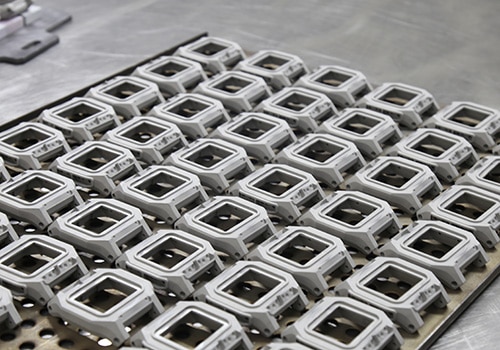

MIM Design

Metal Injection Molding (MIM) combines 2 custom manufacturing technologies: plastic injection molding and powered metallurgy, together to produce MIM parts with intricate and complex 3D geometries. It is the most effective way to produce high density component with comparable mechanical properties to raw metal materials. In addition, it provides greater design freedom and innovation opportunities for your MIM products’ development. ZCMM parts has served critical application in a wide range of industries. The most suitable products for MIM usually have the following characteristics.

MIM Design Characteristics

Complexity: MIM allows high freedom of design, which almost create unlimited shape capability. MIM can combine individual parts into a multiple-functional one without additional cost. There is no doubt that our MIM can adapt to any product easily.

Precision: Net shape precision of MIM parts is ±0.5% in dimension, and certain feature is ±0.3%. For high tolerance, various MIM finishing process can achieve with higher cost.

Weight and Size: MIM is appropriate for parts less than 100 grams, less than 50 grams application is the most economical, and we also can produce parts weight up to 250 grams. Raw material is the key of MIM cost control, so we can use coring and ribs to reduce product weight without damage to product integrity. MIM parts size can reach 250 mm length without limitation.

Section Thickness: Less than 6 mm wall section is most suitable for MIM process. Thicker section will increase cost in reason of longer processing time and additional material. MIM can manufacture thin section less than 0.5 mm depend on your design requirement.

Production Volumes: our MIM is a scaling process, from a thousand parts to millions parts annual with economical schedule.

Application Assistance: ZCMIM will provide our customer most comprehensive assistance to achieve MIM value in process. We will help you with product design, material selection, failure effect analysis, rapid prototyping and laser scanning in production development.