Iron-Nickel Alloy

Introduction

The iron-nickel alloy (nickel-iron alloy) is abbreviated as FeNi or NiFe, it is a group of alloys with primary element of nickel(Ni) and iron (Fe). Depending on the intended application of the alloys, iron-nickel alloys are usually fortified with small amount of other metals, like chromium, cobalt, molybdenum, and titanium.

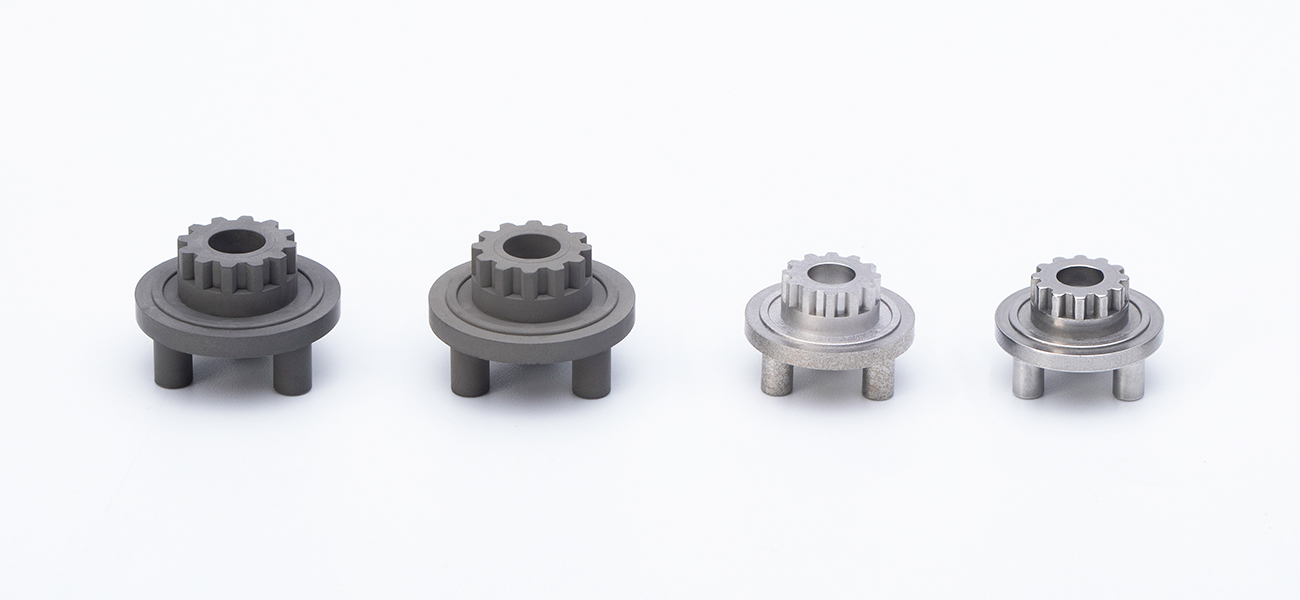

The iron-nickel alloys are applied in mechanical and structural components with high strength and superior surface finish. In addition, heat-treating is the common secondary process to increase both strength and hardness.

Iron-Nickel Alloy Properties

Corrosion of Iron–Nickel Alloys

Nickel-iron alloys are more resistant than iron alloys in salt solutions. However, as the increasing nickel content, these alloys show an increasing tendency in suffer pitting and crevice corrosion.

Magnetic Property

Ni-Fe alloys are the most versatile system of soft magnetic materials. Depending on the nickel content, in range between 30 to 80 wt%. there are maximized properties in either permeability, saturation magnetisation, or electrical resistance. In the nickel concentration of 80%, both anisotropy and magnetoelasticity constents are almost zero. Furthermore, the small amount additions of Mo and Cu can obtain a non-magneto-strictive alloy with zero anisotropy. This enable alloy designs with ideal soft magnetic properties to indicate high permeability of outstanding feature. Moreover, annealing treatment combing with field-induced uni-axial anisotropy can control and adjust the magnetisation process to specific applications.

Magnetic Losses

Iron-Nickel alloys can achieve different magnetic properties by adjusting the composition and preparation process. There is no restraints in common MIM (Metal Injection Molding) manufacturing process. For composition around 80 wt.%Ni (Fe80Ni), the crystal anisotropy and the magnetostriction cross are nearly zero. The deliberate introduction of elements (Mo, Cu, Cr) can yield materials with extremely low hysteresis losses(coercive field less than 1 Am−1). The combination of low hysteresis losses and low classical losses make iron-nickel alloys most suitable for applications at high frequencies.

Nickel-iron Vs Cobalt-iron Alloys

Nickel-iron alloys have a wide range of magnetic properties. The suitable annealing temperatures and high cooling rates can achieve the stable random FCC phase, and finally result in the variety of magnetic behaviors in final Fi-Ni laminations. This can control the final Fe-Ni phase ordering, result in corresponding high permeability and very low coercivity.

Cobalt-iron alloys don’t display significant soft magnetic properties, but represent the unique solution in Curie temperature and saturation polarization. The classical Fe50Co (Fe50-Co50) alloy is very useful in requirement of volume reduction and high working temperature, such as onboard high-speed generators for aircraft and spacecraft. However, since the intrinsically brittle of Fe50Co in cooling process, the Fe49Co49V2 alloy is the best substitution. The vanadium (V) can inhibit atomic ordering, and give rise to ductility behavior of the alloy.

Common MIM Iron-Nickel Alloys

In ZCMIM, we have applied different iron-nickel alloys to produce different MIM part for customers with unique properties. The most common iron-nickel alloy including: MIM 4605, Fe2Ni, Fe4Ni, Fe8Ni, Fe50Ni.

MIM 4605

MIM 4605 is a low alloy steel with element of carbon, nickel and molybdenum. This steel can achieve high hardness and strength by quenching and tempering heat-treatment. In common quenching and tempering process, MIM 4605 provides various strength and wear resistance, with the high hardness of 36HRC.

Normal chemical composition of MIM 4605

| MIM 4605 | Iron | Nickel | Molybdenum | Silicon | Carbon | Sulphur | Phosphorus |

| Percent by Weight | Bal. | 1.50-2.50 | 0.20-0.60 | 1.00 | 0.40-0.60 | 0.03 | 0.035 |

Fe2Ni

Fe2Ni or Fe02Ni alloy has excellent mechanical properties, corrosion resistance, and high temperature stability. This alloy can alter its shape under external magnetic field, and return to original shape after removal of the magnetic field. Fe2Ni alloy is an intelligent material with broad applications, including: industrial automation, medical equipment, MEMS, intelligent buildings.

Normal chemical composition of Fe2Ni (Fe02Ni)

| MIM Fe2Ni | Iron | Carbon | Nickel | Sulfur | Phosphorus |

| Percent by Weight | BaL. | 0.40-0.60 | 1.50-2.50 | 0.00-0.03 | 0.00-0.035 |

Fe4Ni

Fe4Ni or Fe04Ni has excellent tensile and yield strength, it also can achieve hardness of 90 HV10. This MIM material can be applied to produce various MIM parts with excellent properties. In addition, Fe04Ni can be used in different surface treatments, like: polishing, sandblasting, electroplating, coating, wire drawing.

Normal chemical composition of Fe4Ni (Fe04Ni)

| MIM Fe4Ni | Iron | Carbon | Nickel | Sulfur | Phosphorus |

| Percent by Weight | BaL. | 0.40-0.60 | 3.00-5.00 | 0.00-0.03 | 0.00-0.035 |

Fe08Ni

Since Fe8Ni (Fe08Ni) has higher saturation magnetic induction, and lower magnetic permeability, it has both high precision and high sensitivity. In metal injection molding (MIM) technology, it is easy to achieve large-scale production with high precision, low cost, good aesthetics. Fe8Ni has a wide range of applications, like: magnetic heads, sensors, motors.

Normal chemical composition of Fe8Ni (Fe08Ni)

| MIM Fe8Ni | Iron | Carbon | Nickel | Sulfur | Phosphorus |

| Percent by Weight | BaL. | 0.40-0.60 | 7.0-9.0 | 0.00-0.03 | 0.00-0.035 |

Fe50Ni

Fe50Ni (Fe-50%Ni, or Fe50Ni50)has the highest saturation magnetization of 1.6T, it has a higher permeability and better corrosion resistance than silicon-iron alloys. In addition, it also has a high incremental permeability in a wide range of polarizing fields. Therefore, the wide range of properties can be achieved by various post-processing techniques. The main application of Fe5oNi includes chokes, relays, small motors.

MIM-Fe50Ni has the hallmark magnetic properties for this alloy, with the high permeability and low coercive field. This iron-nickel alloy is applied in switches & relays, motors, and magnetic shielding applications. In addition, this alloy is used for hermetical sealing packages in electronic and optical-electronic applications. It has excellent thermal expansion characteristics in glass-to-metal seals.

Normal chemical composition of Fe50Ni (FeNi50)

| Fe50Ni | Iron | Nickel | Silicon | Carbon | RoHS Compliant |

| Percent by Weight | Bal. | 49.0-51.0 | 1.00 | 0.05 | Yes |

Ni-Rich Alloys

As the nickel content increase, especially over 35% in weight, iron-nickel alloy will display different magnetic properties over low nickel content. The high permeability of nickel-iron alloys are suitable for the electronic communication and electrical power engineering industries. The high permeability at low fields provide a wide range of applications for minimizing core sizes.

Ni-rich alloys are also known as Permalloys, these alloys have high-permeability. There are four important permalloy compositions.

- Fe80Ni (80% Ni Permalloy), it has near zero level in both anisotropy and magnetoelasticity. This alloy is also known as Supermalloy, Mu metal, Hi-mu 80.

- Fe65Ni (65% Ni Permalloy), it has KI~0, and exhibits the strong response to field annealing.

- Fe50Ni (50% Ni Permalloy), this alloy has higher Bs, strong response to field annealing, it is the suitable square-loop materials.

- Fe36Ni(36% Ni Permalloy), it is less costly than Fe5oNi, but has lower saturation magnetization and permeability.

Normally, the magnetic properties and response to field annealing are induced by anisotropies in permalloys, which are determined by two intermetallic phase structure: disordered FCC, ordered L12 Ni3Fe.

FeNi80

FeNi80 (80% Ni Permalloy) is also called Fe20Ni80, Supermalloy, Mu metal, Hi-mu 80. It is a well-known thin film alloy for applications of magnetic thin film recording heads and MEMS. This alloy is the key magnetic material in the magnonics field. Fe20Ni80 has excellent properties with lower overpotential and higher current density.

Normal chemical composition of FeNi80

| FeNi80 | Iron | Nickel | Chromium | Silicon | Manganese | Copper | Carbon |

| Percent by Weight | Bal. | 79.0-81.5 | 2.60-3.00 | 1.10-1.50 | 0.60-1.10 | 0.20 | 0.03 |

Fe35Ni65

Fe35Ni65 has the low anisotropy constant K1, nearly close to 0. This alloy has excellent response to annealing, such as the corecivity of Fe35Ni65 films at 600 ℃ have large value.

Normal chemical composition of Fe35Ni65(FeNi65)

| FeNi80 | Iron | Nickel | Silicon | Carbon |

| Percent by Weight | 34.0-35.0 | 62.0-65.0 | 1.00-1.50 | 0.03 |

FeNi36 (Invar)

As FeNi36 (64FeNi) is less costly than Fe50Ni, it has high resistivity, lower saturation magnetization, lower permeability. This alloy is Invar type, it has a low coefficient of expansion at 1 × 10−6°C−1. This ally are applied for relays, inductors and high-frequency transformers, where the higher resistivity limits the eddy currents.

Normal chemical composition of FeNi36 (64FeNi)

| FeNi80 | Iron | Nickel | Manganese | Silicon | Carbon | Sulphur | Phosphorus |

| Percent by Weight | Bal. | 35.0-37.0 | 0.20-0.60 | 0.30 | 0.05 | 0.02 | 0.02 |

IN718

Inconel 718(IN718) is a nickel-based supper-alloy with high strength, oxidation resistance and heat corrosion resistance in high temperature applications. This makes it apply widely in high temperature applications, nuclear and petrochemical industries.

Normal chemical composition of IN718 (Inconel 718)

| MIM IN718 | Iron | Nickel | Chromium | Niobium | Molybdenum | Cobalt | Titanium | Aluminum | Manganese | Copper | Silicon | Carbon |

| Percent by Weight | BaL. | 50.0-55.0 | 17.0-21.0 | 4.75-5.50 | 2.80-3.30 | 1.00max | 0.65-1.15 | 0.20-0.80 | 0.35max | 0.30max | 0.35max | 0.08max |

Conclusion

Iron-nickel alloys are the second popular material in MIM. Regardless common mechanical properties, these alloys also have excellent magnetic properties. This make these alloys apply widely in various electronic industry. ZCMIM, as the top MIM company in China, is able to produce custom iron-nickel alloys for various application in worldwide.