IN718 MIM

Introduction

Inconel 718 (IN718) is a nickel-based supper-alloy with high strength, oxidation resistance and heat corrosion resistance in high temperature applications. This makes it apply widely in high temperature applications, nuclear and petrochemical industries.

Supperalloys are heat-resisting alloys on base of nickel-iron or cobalt, these alloys have high strength, satisfactory oxidation resistance, heat corrosion resistance at elevated temperatures. These properties are suitable for specific applications in high temperatures, automotive, medical, chemical, and petrochemical industries. However, these high strength and toughness are also difficult to shape by machining or forging. Metal injection molding provides an economical alternative in In718 fabrication.

IN718 Metal

Inconel 718 (IN718) can achieve the most demanding high temperature applications, it is a γ precipitation-hardenable nickel-chromium alloy. Due to the low carbon level, IN718 combines high strength and corrosion resistance with outstanding weldability. This alloy also has excellent creep-rupture strength at 700℃, which makes it apply in in aerospace engines and stationary gas turbines, rocket motors, spacecraft, nuclear reactors, pumps, and tooling.

IN718 is strengthened primarily by γ precipitates (Ni3Nb) with BCT crystal structure and γ intermetallic compounds (Ni3(Al,Ti)) with FCC structure in austenitic matrix. Another prominent phase of δ (Ni3Nb) with an orthorhombic crystal structure can control grain size and improve stress rupture ductility in IN718.

Chemical Composition

| MIM IN718 | Iron | Nickel | Chromium | Niobium | Molybdenum | Cobalt | Titanium | Aluminum | Manganese | Copper | Silicon | Carbon |

| Percent by Weight | BaL. | 50.0-55.0 | 17.0-21.0 | 4.75-5.50 | 2.80-3.30 | 1.00max | 0.65-1.15 | 0.20-0.80 | 0.35max | 0.30max | 0.35max | 0.08max |

Form the chemical analysis, MIM and heat treatment process never affect the chemical composition of IN718. In order to avoid degrading of ductility, the oxygen control in MIM process is critical. The 0.2 wt.% region of oxygen content is the detrimental level to elongation. In addition, the maximum carbon content for IN718 is 0.08 wt.%, the composition variation of +/-0.01% is not detrimental to the final parts.

Mechanical Properties

| Material | Density | Tensile Strength | Yield Strength(0.2%) | Elongation(% in 25.4mm) | Hardness | CTE (20-100 ℃) |

| MIM IN718 | ≥8.19g/cm³ | ≥965 Mpa | ≥550 Mpa | ≥12% | 47 HRC | 13.0 μm/m°C |

IN718 can reach 98% density at 1270°C sintering, and achieve nearly full density after HIP. The tensile strength and yield strength decrease after HIP, precipitation aging and solution treatment, while elongation increases.

MIM IN718 Properties

After sintering, the UTS (Ultimate Tensile Strength) and PS (Press Strength) of MIM IN718 is higher than cast-equivalent IN 718, while inferior to wrought 718 alloys. Heat treatment has significant effect on tensile strength and proof strength. After precipitation ageing, the UTS and PS strength are higher than cast, wrought 718.

In sintering process, the liquid phase increase at 1270℃ will increase as super-solidus liquid phase take place. Then the Ni3Nb phase precipitates and resolves into the solid phase. These grain boundaries are not enough for adequate mechanical properties. After heat-treatment or ageing, the strengthening phases are formed, and increase the UTS & PS.

After HIPing, the density of MIM IN719 will increase, due to the high temperature and high pressure, grain displacement and plastic deformation eliminate the pores in MIM parts. Finally increase the elongation.

IN718 Micro-structure

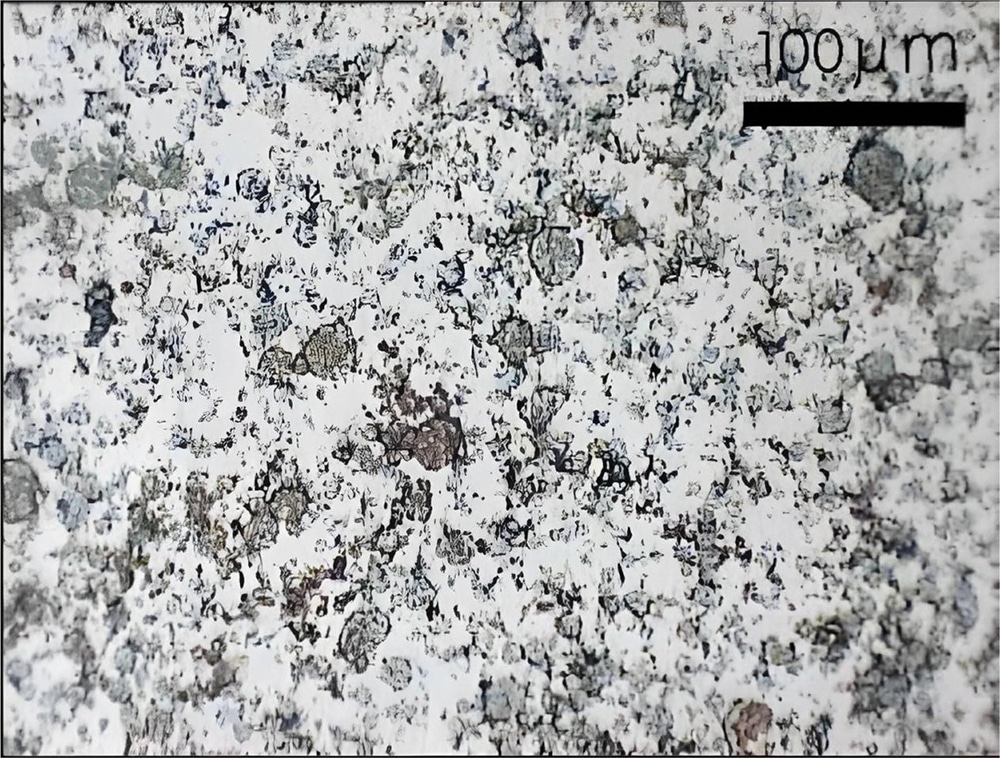

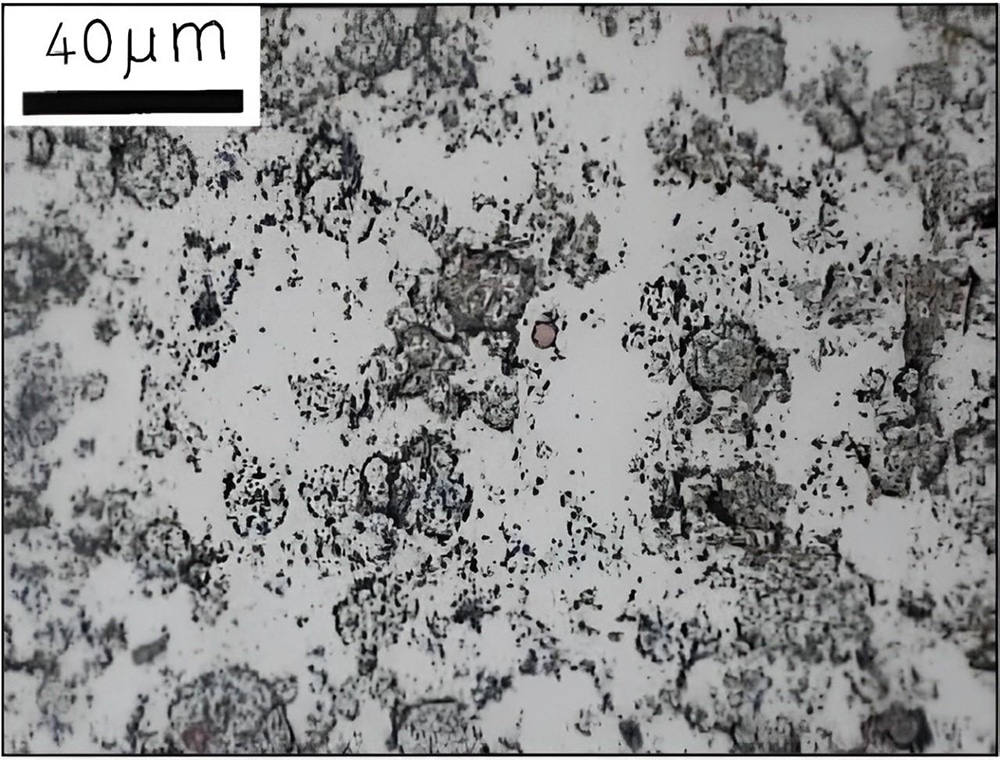

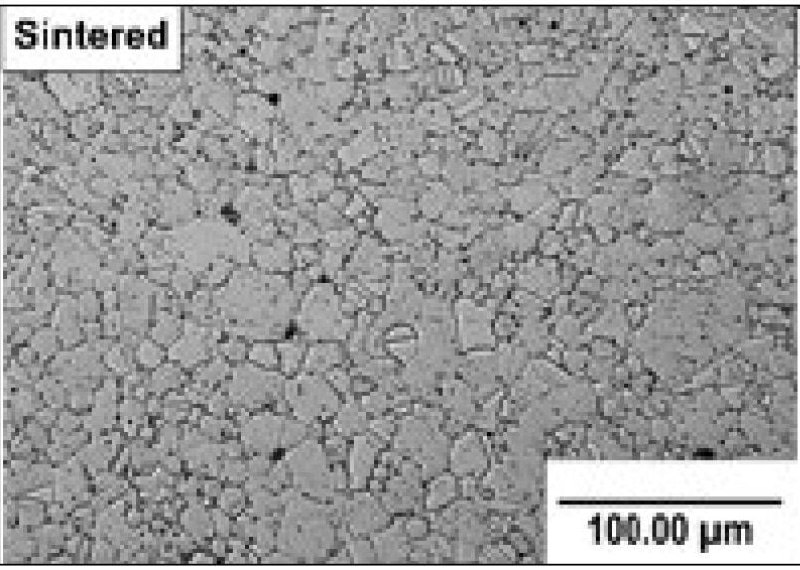

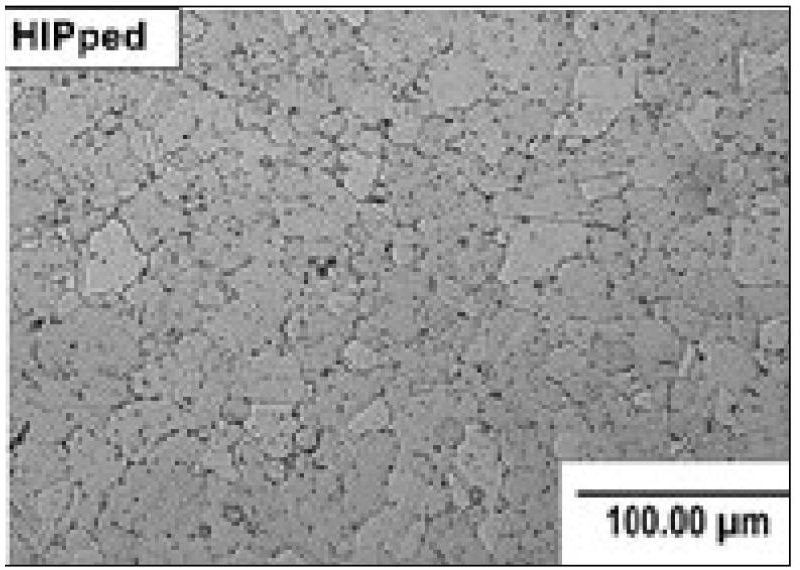

From the optical micro-graph of sintered Alloy 718 after polishing and etching, there are fine grain size and precipitates.

718 Micrograph after polishing

718 Micrograph after etching

The following picture demonstrates the micro-structure of heat-treat IN718. The heat treatment can improve the homogeneity significantly, specially in the grain size with even distribution.

Surface micrograph of sintered 718

After HIP treatment, the pores on IN718 surface are eliminated. It is obvious in the following micro-graphs. There are some dark particles at the triple points of grain boundaries, it is normal oxides and carbides. HIP can increase the grain size from about 10 µm to 15 µm.

Surface micrograph of HIPed 718

IN718 Micro-structure Evolution

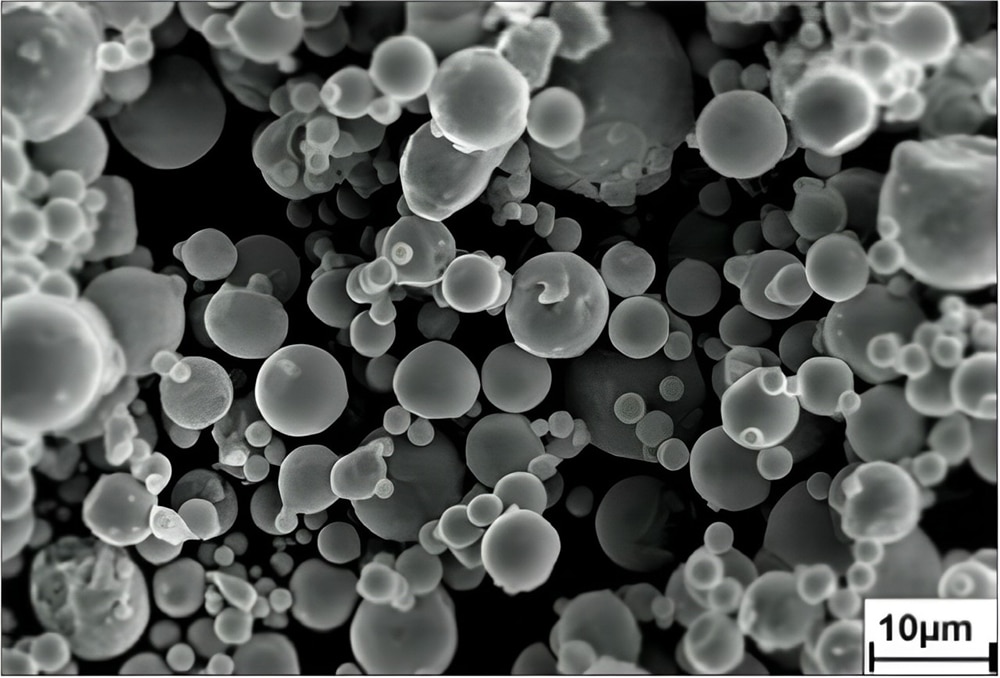

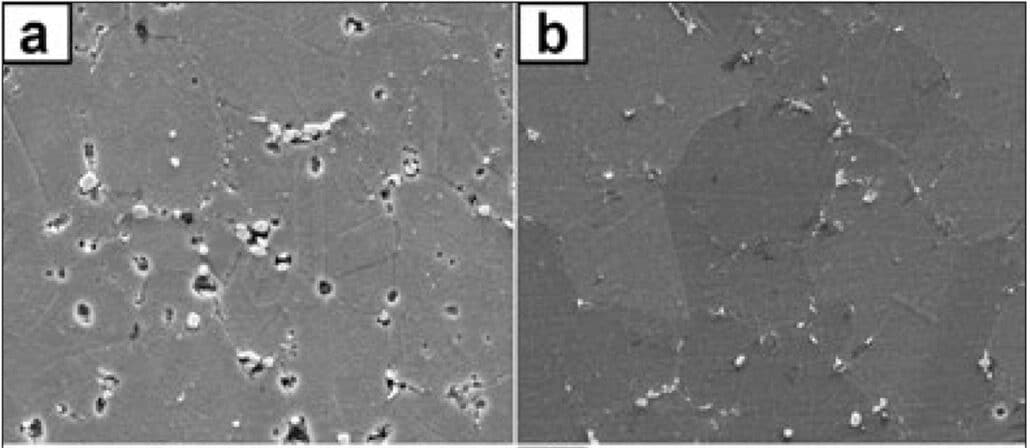

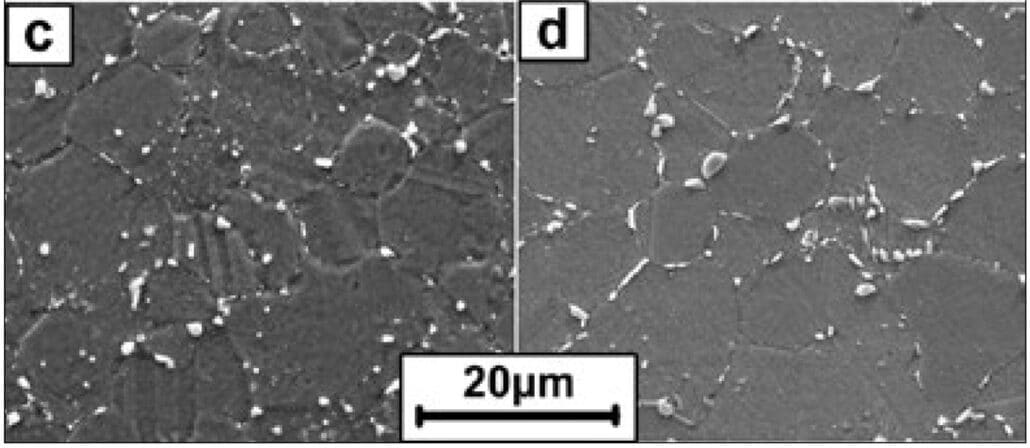

From the SEM micro-graphs, the evolution of IN718 micro-structure is displayed in following pictures:

In sintered state, there are uniform distribution of the secondary phases, and residual pores on surface.

After HIP, the secondary phase precipitates are reduced, the residual pores are eliminated.

In the solution treatment, the volume of secondary phase precipitates are higher than HIP condition, this is found at the grain boundaries and inside the grains.

After precipitation ageing, the precipitation of secondary phases are confined to the grain boundaries.

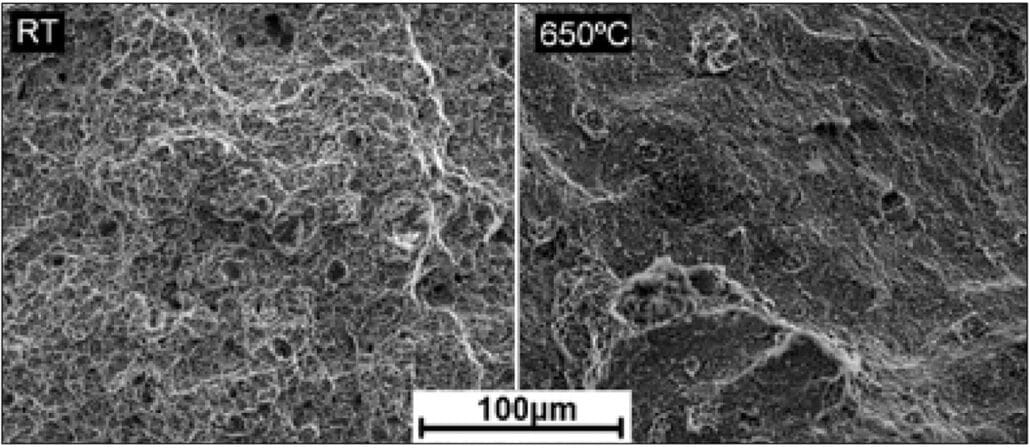

Ductile Fracture Surface

From the SEM graph in fracture surface of heated-treated IN718, there are a few large prior particles, which will restrict the ductility.

In addition, there are a few particle boundary facets and a lot more areas of fine dimples in sintered fracture surface at room temperature. While at 650°C, there are no particle boundary facets, due to the fracture occurs at the precipitate interfaces.

IN718 MIM Strategies

Master alloy powder provides an effective alternative to pre-alloy powders, this powder can enhance the properties of MIM IN718. Comparing to casting IN718, master alloy approach provides economical net-shape components with superior properties. The homogeneous fine-grain micro-structure in mater alloy can ensure these properties in high temperatures.

Conclusion

IN718 is new material in MIM technology. ZCMIM has more than 15 years of experience in different alloys. We can apply IN718 in new MIM project. Contact us for your next MIM project of IN718.