IN713C MIM

Introduction

In713C is a nickel base super-alloy in the most demanding environments of aerospace and powder generation applications. IN713C is the precipitation hardenable variety of industrial nickel-base supper-alloy. Nitrogen atomisation has significant effect on properties of sintered IN713C, There are two different types of IN713:

- IN713C with carbon contents in range of 0.08 to 0.20 wt.%

- IN712LC contains 0.03-0.07 wt.% carbon

Chemical Composition

| MIM IN718 | Nickel | Chromium | Aluminum | Molybdenum | Niobium | Titanium | Carbon | Zirconium | Iron | Copper | Silicon | Manganese |

| Percent by Weight | BaL. | 12.0-14.0 | 5.50-6.50 | 3.80-5.20 | 1.80-2.80 | 0.50-1.00 | 0.08-0.20 | 0.0.5-0.15 | 2.50max | 0.50max | 0.50max | 0.25max |

IN713C contains about 8% Al+Ti combined phase, which leads to the high volume fraction of ordered γ′ -Ni3(Al, Ti) as the major strengthening phase. This increase the operating temperature of IN713C up to 850°C. IN713C is the preferred material for engine manufacturer, it can withstand temperature above 1000°C.

Cr, Al perform the critical function in IN713C, these elements form a protective and adherent oxide film (Cr2O3, Al2O3) on the alloy surface. These protective coating provide the wide applications with resistance to aggressive high-temperature oxidization, aqueous corrosion and sulphide attack.

Mechanical Properties

| Material | Density | Tensile Strength | Yield Strength(0.2%) | Elongation(% in 25.4mm) | Hardness | CTE (20-100 ℃) |

| MIM IN718 | ≥7.91g/cm³ | ≥760 Mpa | ≥690 Mpa | ≥3% | 30-42 HRC | 5.92 μm/m°C |

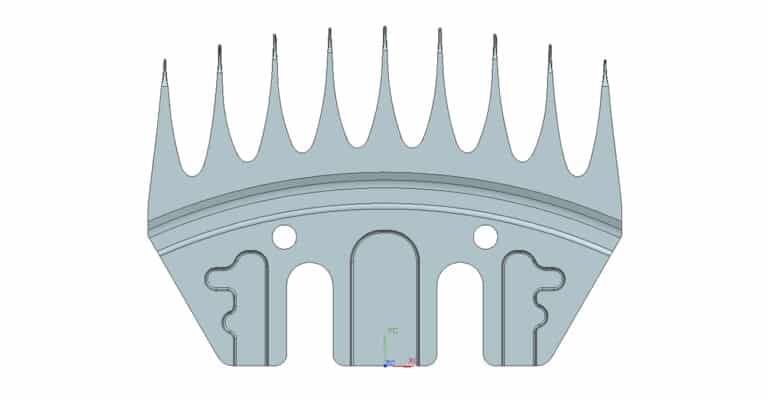

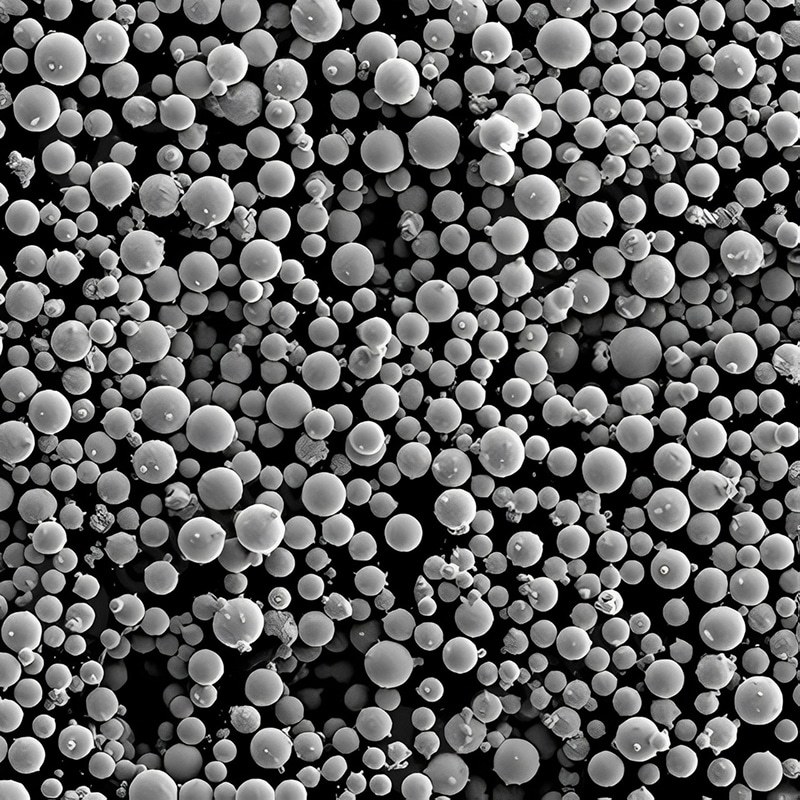

IN713C Powder

Casting IN713C are applied widely in aircraft engines and gas turbines, although these parts are prone to defects, and have limitation on section thickness. MIM technology provides homogeneous part properties in thin-wall structures. IN713C powders are normally produced by argon insert gas atomisation, in order to avoid oxidation of alloy and ensure final density.

IN713C Sintering

In IN713C sintering, the density can achieve 96.5% at temperature of 1250°C, while 98.6% density at 1260°C, 99.2% at 1270°C. Otherwise, typical sintering with HIP process is easy to achieve full densification (>99% theoretical density). The tramp element like carbon, oxygen, and nitrogen are critical with final property performance.

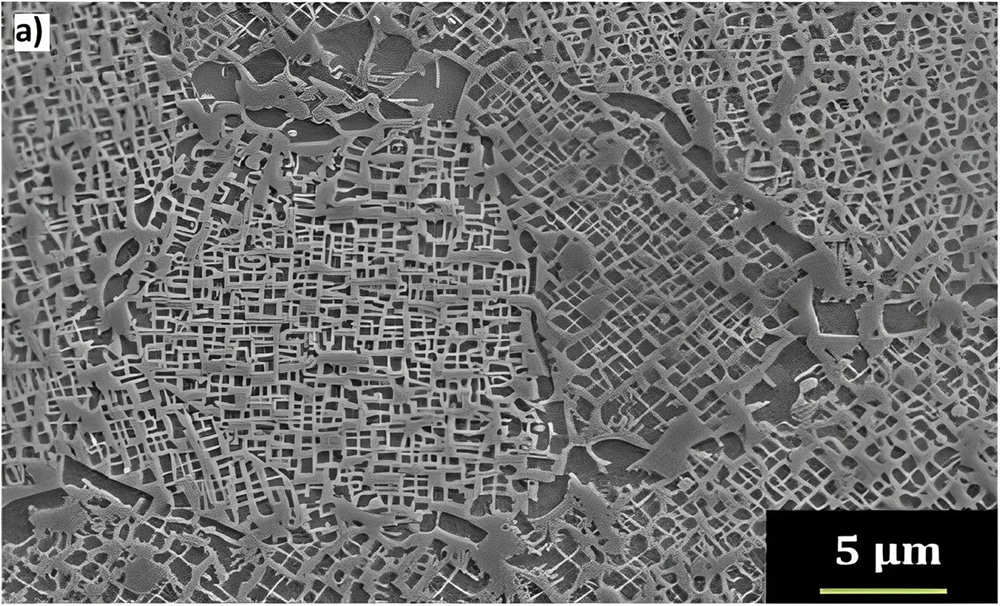

713C Sintering 1250°C

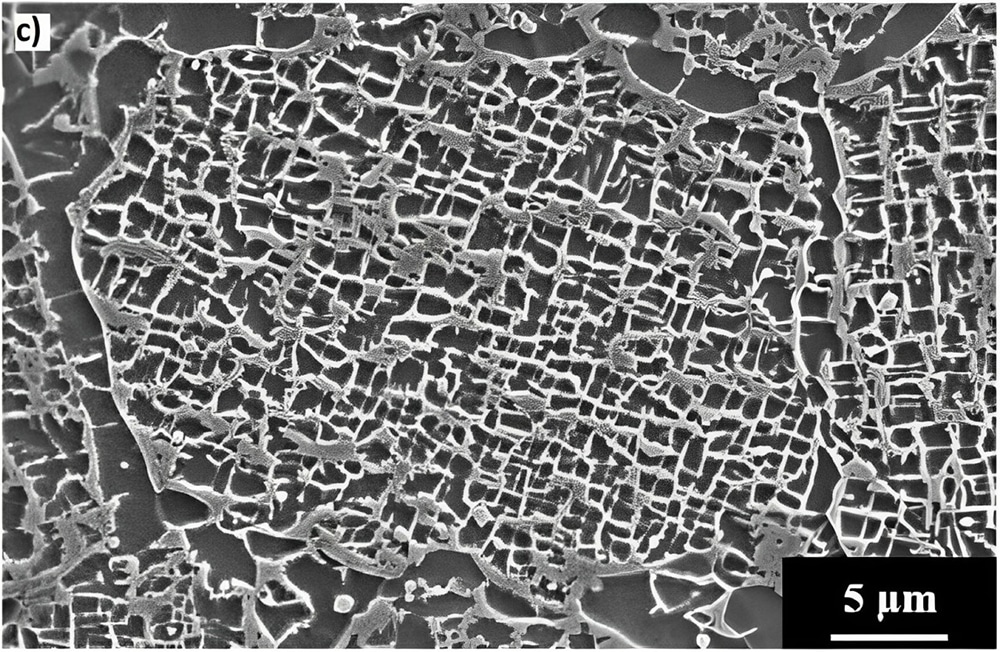

From the following micro-structure of as-sintered IN713C after different temperature sintering, there are white network-like γ continuous matrix with dark γ′ segregated precipitates embedded into the γ matrix.

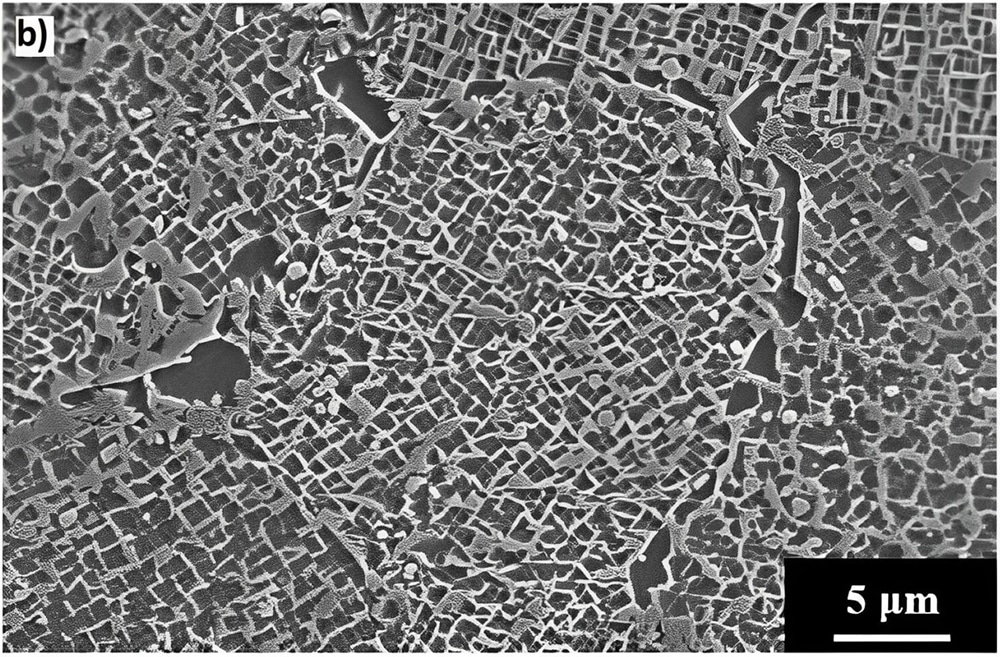

713C Sintering 1260°C

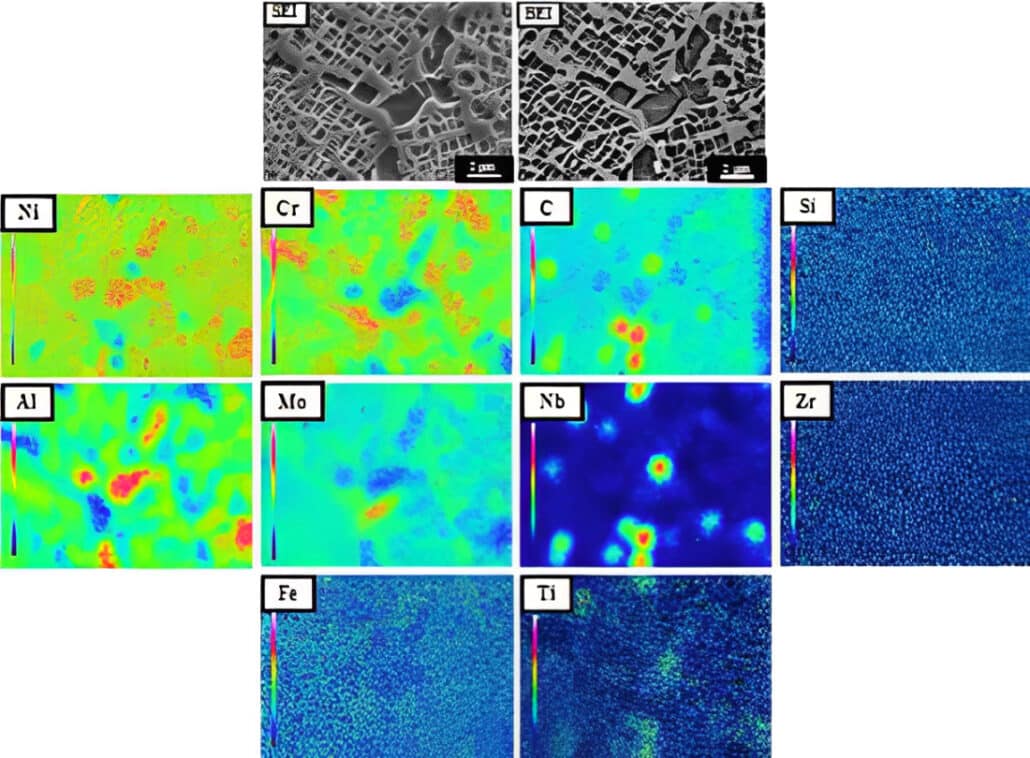

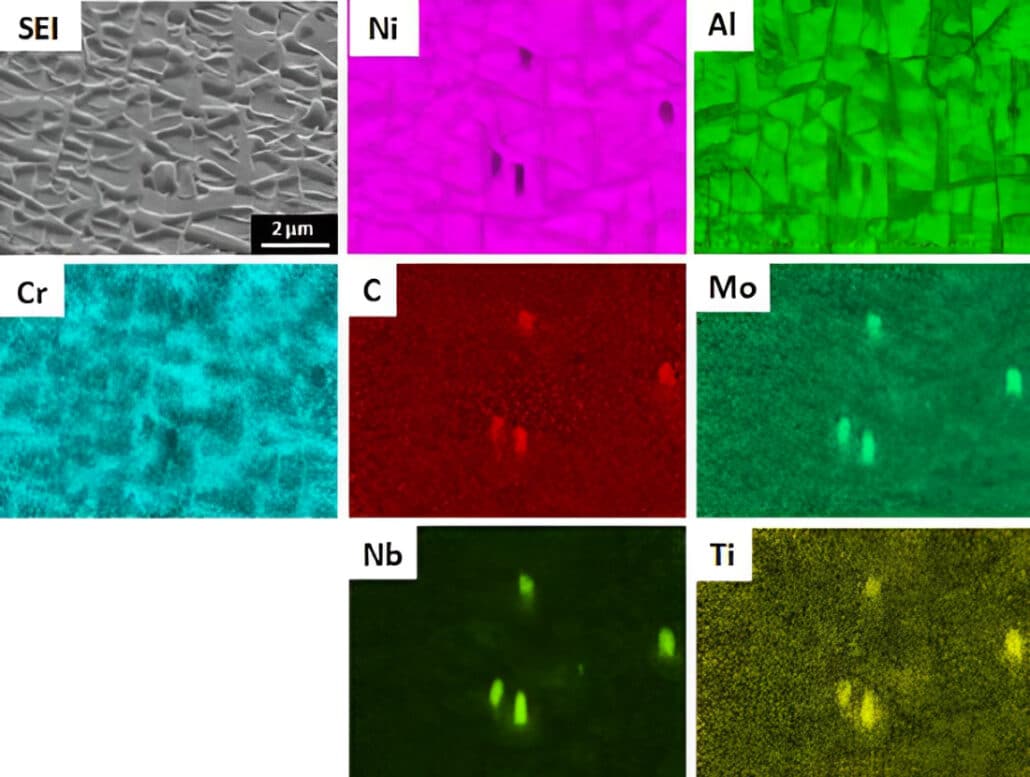

From the EPMA quantitative chemical composition of 1260°C sintered. The Cr, Fe and Mo composition are relatively higher in γ phase, while Al, Ti and Ni are higher in γ′ phase. In addition, there are spherical precipitates of C, Ti, Nb, and Mo abundant metal carbide with 0.2 to 0.4 µm size.

713C Sintering 1270°C

Although IN713C powders are sintered in nitrogen gas atomisation process, nitride compounds are virtually absent in MIM sintered parts.

IN713C Element Control

Carbon Content

There are high carbon content in MIM components of IN713C, this indicates the substantial amounts of carbides on grain boundaries. Although carbides can provide high-temperature strength, they also have detrimental effects on tensile properties. Especially on grain boundaries and inside grains, these are initiation sites for cracks.

EPMA elemental mapping in 1260°C sintering

EDS elemental mapping in 1260°C sintering

Oxygen Content

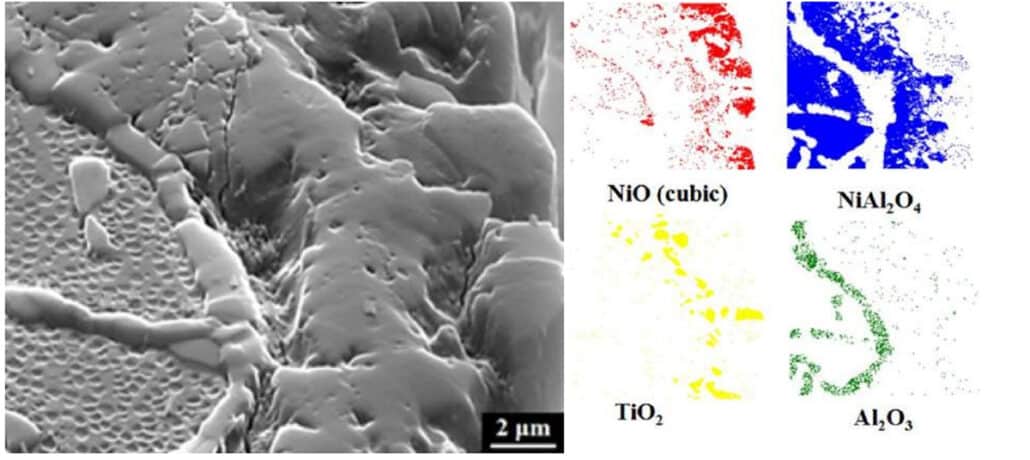

The high oxygen content will lead to the formation of unwanted oxides in IN713C sintering. The oxides have similar detrimental effects on tensile properties.

EBSD phase mapping of oxidation

Oxidation Resistance

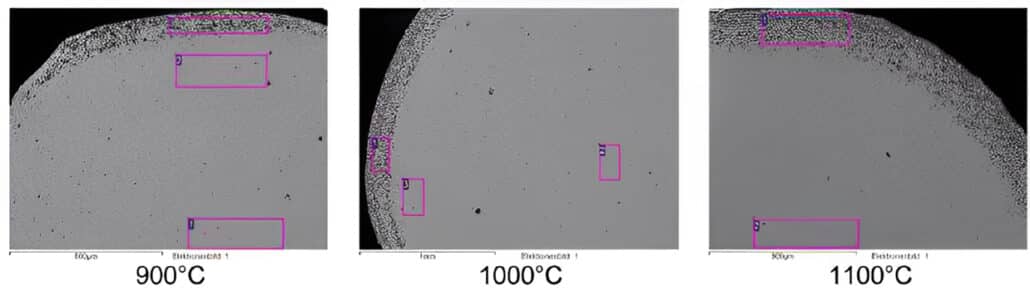

MIM IN713C has excellent oxidation resistance, specific in temperature between 900-1100°C. Al2O3 and Cr2O3 can form as protective oxide scales. At 900°C, Al2O3 is pronounced, while at 1000°C-1100°C, both oxides are formed.

Based on the following image of overall oxide thickness, it increases with temperature from 136 µm (900°C) to 264 µm (900°C). In addition, there is no further internal oxidation under the scales and porous edge region. Therefore, MIM IN713C is able to passivate under oxidizing conditions.

IN713C SEM image after oxidation

Conclusion

IN713C is new material in MIM technology. ZCMIM has more than 15 years of experience in different alloys. We can apply IN713C in new MIM project. Contact us for your next MIM project of IN713C.