F15(Kovar)MIM

Introduction

Kovar (MIM F15) is a nickel-cobalt ferrous alloy with specific properties, it has low coefficient of thermal expansion (CTE), this makes it applied most commonly in electronic applications. In addition, it also used for metal-to-glass sealing in different industries.

F-15 has high nickel and cobalt content, it can withstand rapid temperature changing without structure weakening and deformation. This makes it applied in aerospace industry from absolute zero to extremely high heat.

Kovar(ASTM F15) is a well-characterized MIM materials in electronics and optoelectronic applications for hermetically sealed packages. Its thermal expansion characteristics match that of borosilicate glass, this enables the application of metal-glass or metal-ceramic interfaces.

MIM F15

The chemical composition of MIM F15 is well controlled within narrow limits, so it provides low and uniform thermal expansion properties.

F15 (Kovar) Composition

| MIM F15 | Iron | Nickel | Molybdenum | Silicon | Carbon | Chromium | Cobalt | Copper | Niobium | Magnesium | Titanium | Zirconium | Aluminum | RoHS Compliant |

| Percent by Weight | BaL. | 29 | 0.20 | 0.20 | 0.04 | 0.20 | 17 | 0.20 | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 | Yes |

F15 (Kovar) Mechanical Properties as Sintered

| Material | Density | Tensile Strength | Yield Strength(0.2%) | Hardness | Elongation (% in 25.4mm) | CTE (20-400℃) | Curie Temperature | Thermal Conductivity |

| MIM F15 | 7.85g/cm³ | 450Mpa | 300Mpa | 65HRB | 25% | 4.5 (10^-6/℃) | 435℃ | 17.3 W/m.K |

Magnetic Properties

MIM F15 is magnetic at all temperature below Curie point. In addition, magnetic properties will also depend on heat treatment, the lower hardness will achieve the higher permeability values and lower hysteresis loss.

| ASTM F15 CTE | 30℃-400℃ (10-6/K) | 30℃-800℃ (10-6/K) |

| MIM sintering | 4.20-4.80 | 9.60-10.20 |

| Molten manufacturing` | 4.60-5.20 | 10.40 |

Thermal Expansion Properties

Kovar alloy has low coefficient of thermal expansion (CTE) similar to hard (borosilicate) glass. This provides the hermeticity for firmly bonding between metal and glass. In order to protect electronic or optical devices in hermetic enclosures or packages. The low CTE of kovar alloy is suitable for matched-expansion seal between metal and glass parts.

The Nominal CTE (Coefficient of Thermal Expansion) of MIM F15

| Temperature Range | CTE (10^-6/℃) |

| 20℃ – 400℃ | 4.50 |

| 30℃ – 400℃ | 4.90 |

| 25℃ – 300℃ | 5.13 |

| 30℃ – 450℃ | 5.30 |

| 25℃ – 100℃ | 5.86 |

| 25℃ – 500℃ | 6.15 |

| 25℃ – 900℃ | 11.26 |

MIM F15 Heat Treatment

Heat treatments have actual effect on micro-structure of MIM F15, this can facilitate manufacturing process to ensure final property and geometry requirements. Otherwise, we should notice that Kovar is non hardenable by heat treatment.

Common Annealing

Common annealing are processing at 788℃ temperature for 1 hour, then cooling down in air atmosphere.

Stress Relief Annealing

This annealing process can relieve stress and hardening in MIM sintering process. The annealing temperatures are no greater than 900℃, and extended time periods are no longer than 60 minutes. In order to avoid grain boundary growth. The typical cycle of stress relief annealing is 850℃ for 30 minutes. MIM parts need to be held at temperature for the indicated time, then cooled down to less than 175℃ in furnace, in order to avoid oxidation or thermal shock.

Oxidation Heating

Heat F15 parts to 850-900℃ in the electric air furnace, until F15 part reach to cherry red or dull red color. The heating cycle is approximately 3 minutes. Then reduce heat about 10℃ per minute, the oxide will form once parts are cooled down. The oxide has appearance color from light grey to black.

Kovar Secondary Process

After MIM sintering process, there are different secondary process for geometry improvements.

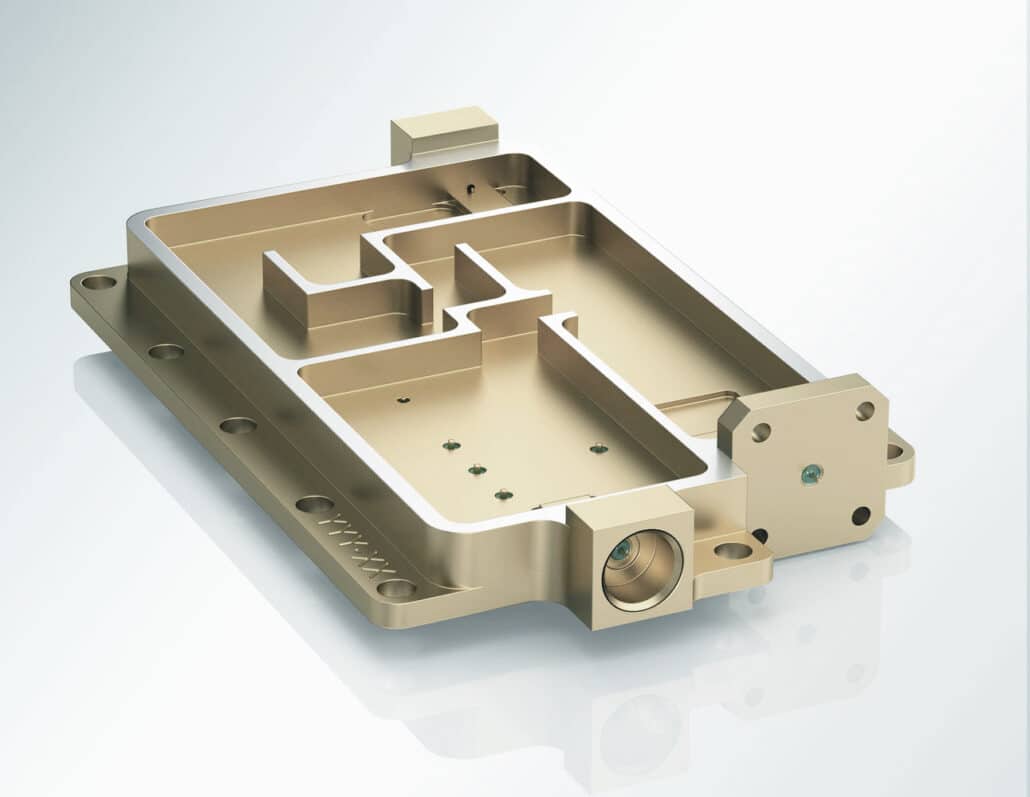

Machining

Sintered Kovar parts are easy machined by the conventional methods. CNC machining is the most common method to ensure the critical tolerance in specific areas.

Welding

MIM F15 parts are also performed by traditional welding methods, this provide multiple options for complex geometries.

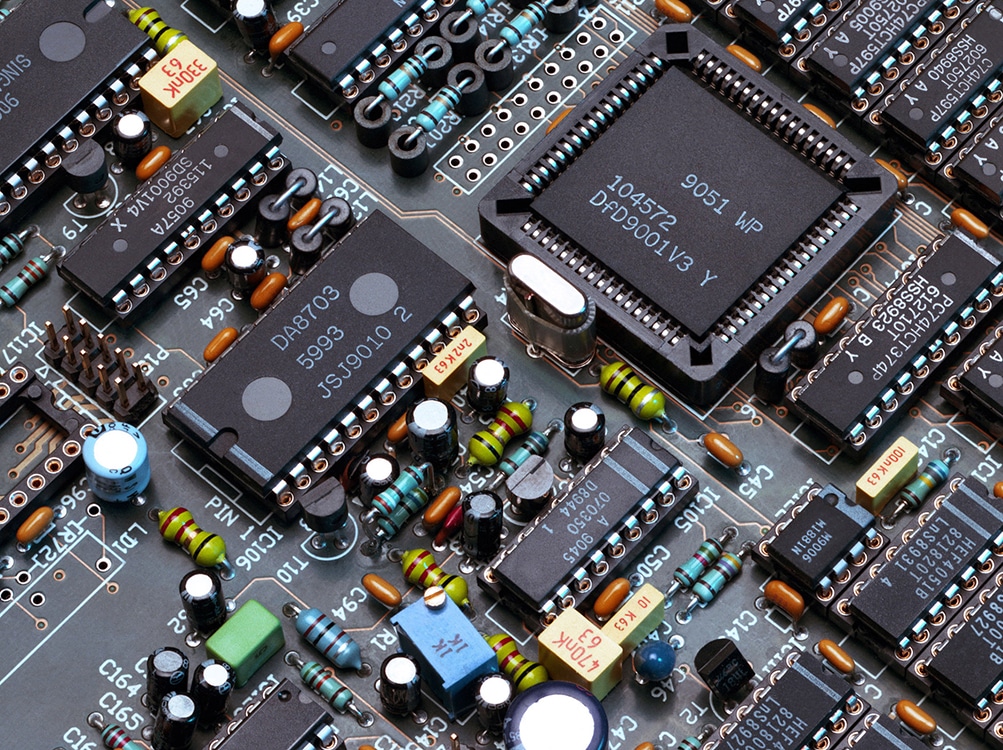

MIM F15 Application

Kovar is a common MIM material, it has the substantially same thermal expansion characteristics as borosilicate glass. This enables the tight mechanical joint between these two materials over in a temperature range.

F15 alloys have similar characteristics as multiple glass and ceramic components. Custom composition with specific non-linear thermal expansion curve are designed to match mating materials. Except borosilicate glass, Kovar also has good CTE match for other materials, like aluminium nitride, shapal, germanium, sapphire.

Kovar alloys are applied for hermetic seals with harder glasses and ceramic materials, such as powder tubes, x-ray tubes, microwave tubes, transistors, diodes, intergrated circuits.

Common MIM F15 Application:

- Hermetic sealing

- High-power transmitting valves

- Transistor leads and headers

- Integrated-circuit lead frames

- Integrated circuits packaging

- Scientific instruments

- Microwave tubes

- Hybrid packages

- Power tubes

- Transistors

- Diodes

Conclusion

ZCMIM has more than 15 year experience in MIM F15. We apply different alloy proportion, powder size, sintering parameter to achieve specific mechanical and CTE properties. Contact us for your next MIM F15 project.