Cobalt MIM

Introduction

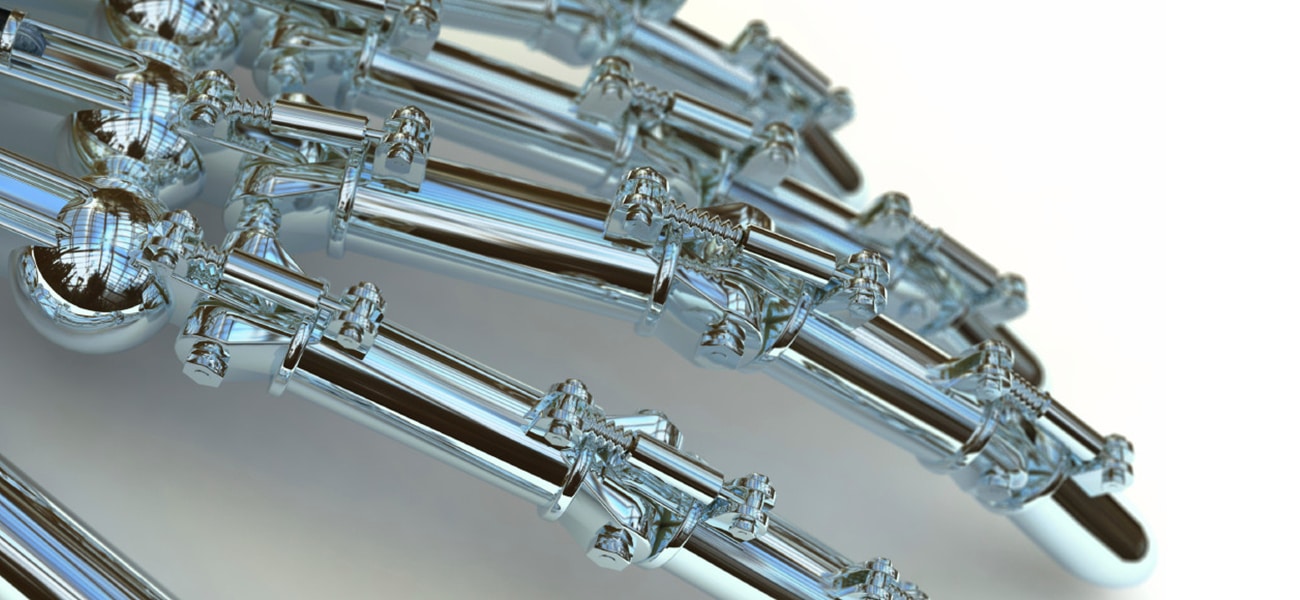

Co-MIM combines cobalt alloy powders with conventional MIM process, in order to create functional parts with high toughness and wear resistance. Then satisfy the requirements of superior mechanical properties.

Cobalt Alloys for MIM are materials, cobalt is core alloyed with other metals like chromium, tungsten, nickel and iron. Similar as nickel-based alloys, cobalt alloys are applied in tough and challenge environments with high temperatures and acids.

MIM Cobalt alloys are applied in requirement of excellent corrosion and wear resistance. Gas turbine generators, jet engine turbines are typical application for MIM Cobalt alloys. In addition, dental and medical implants are two common Co-alloy applications.

Cobalt Alloys

Cobalt (Co) is naturally ferromagnetic, it is the most common additives in metalworking as the strengthening element. Cobalt alloys are corrosion, wear and heat resistant. In addition, cobalt displays excellent resistance against sulfides, cobalt alloys can prevent any sulfidation.

Cobalt-based alloys are cobalt-basis metal with alloy elements like chromium, tungsten, nickel, molybdenum, and iron. Similar as nickel-based alloys, cobalt alloys are applied in challenging environments with high temperatures and acids.

Cobalt alloys have major mass fraction of cobalt. The base combinaion of most cobalt alloys is chromium, chromium acts as a strengthening alloy. tungsten or molybdenum can also improve alloy strength. Nickel is another common element in many cobalt-based alloy, it is more heat resistant than cobalt, this can wide the temperature rage of alloy resistance. Therefore, cobalt alloys have good magnetic properties, corrosion and wear resistance, high temperature strength.

Cobalt-based Alloys VS Nickel-based Alloys

Although cobalt-based alloys have excellent mechanical properties, comparing to nickel-based alloys, cobalt-based alloys are rarely applied. In most high-temperature applications, nickel-based alloys are preferred because of significantly lower prices and wider range.

Both cobalt and nickel alloys have similar properties of excellent heat, wear and corrosion resistance. Nonetheless, Co-based alloys provide superior strength at high temperatures than many nickel-based alloys.

Special Properties of Cobalt Alloys

Low Thermal Expansion(CTE) is one key specific property of Cobalt Alloys, for example: ASTM F15 (Co17-Ni29-Fe54)

| ASTM F15 CTE | 30℃-400℃ (10-6/K) | 30℃-800℃ (10-6/K) |

| MIM sintering | 4.20-4.80 | 9.60-10.20 |

| Molten manufacturing` | 4.60-5.20 | 10.40 |

Cobalt alloys have common properties of wear-resistance, corrosion-resistance, heat-resistance. These characteristics are still strong even at high temperatures. All these properties are determined by the different factors in cobalt alloys:

- Crystallographic nature of cobalt (in particular response to stress)

- Solid-solution-strengthening effects of chromium, tungsten, and molybdenum

- Formation of metal carbides

- Corrosion resistance imparted by chromium

Cobalt MIM Sintering

Carbon Control

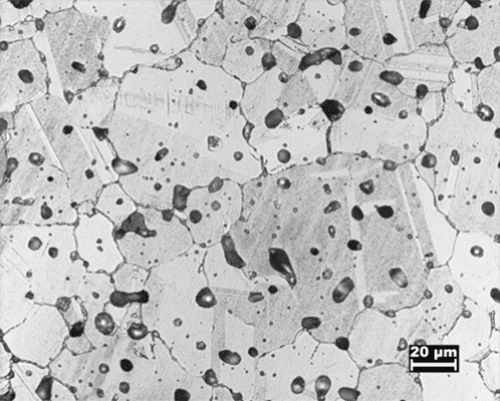

Carbon element in cobalt MIM sintering, can form grain boundary carbides, this is detrimental to mechanical properties, especially ductility. In addition, chromium carbides can form the eutectic to reduce incipient melting as low as 1200℃. In order to eliminate any grain boundary carbides, cobalt alloys are heating above 1200℃, then rapid cooling to prevent carbide precipitation.

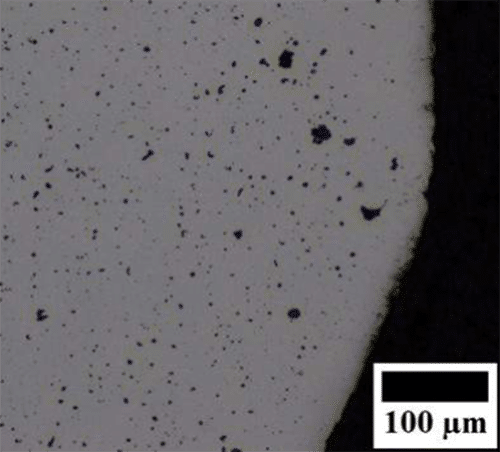

Metallographic structure of F75 sintering

Nitrogen Control

Nitrogen is the alternative element of carbon, it can increase the strength of cobalt alloys with good ductility. MIM sintering process is better suited to nitrogenization, because open pore structure facilitates the uniform introduction of nitrogen as an interstitial solute. The nitrogen concentration will reach to 0.35% at 1200℃ in Co-28Cr-6Mo alloy. This is expected from the nitrogen-strength effect, nitrogen sintering will increase both yield and ultimate strength.

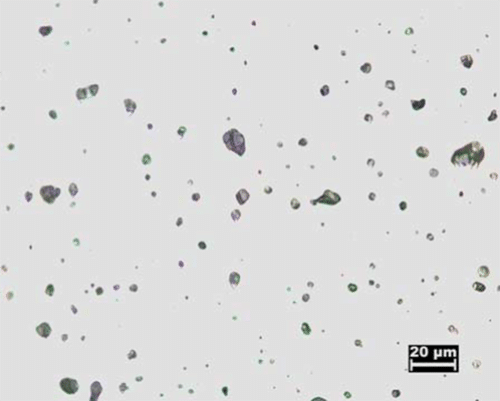

Micrograph after Sintering

HIP Process

HIP process can decrease the porosity, this will increase the elongation, yield strength, and UTS(ultimate tensile strength).

Co-Alloys have different grades. Normally, the tougher and softer compositions are applied in high-temperature applications, such as gas-turbine vanes and buckets. While, the harder grades are in wear-resistance applications, like cobalt-chromium-tungsten and cobalt-chromium-molybdenum are two commercial cobalt alloys. Tungsten(W) and Molybdenum(Mo) are two powerful strengthening agents in cobalt-chromium alloy system.

Micrograph after HIP

Co-Cr-W MIM

In gas turbine industry, there are high requirements of materials in elevated-temperature strength, resistance to thermal fatigue, and oxidation resistance. However, in land-base gas turbines, sulfidation resistance is the major concern, as lower grade fuels is burned with lower operating temperatures.

Although Co-Cr-Ni-W alloy are not as widely as nickel alloys in high temperature applications, Co-Cr-Ni-W alloy still have high strength at temperatures exceeding the gamma-prime- and gamma-double-prime-precipitates in the nickel and nickel-iron alloys dissolve. Due to the excellent resistance to sulfidation at high temperatures.

Indead, the main difference in Co-Cr-W alloy grades are carbon and tungsten contents. Such as the amount and type of carbide formation in micro-structure during MIM sintering process. Carbon content affect final hardness, ductility, abrasive wear-resistance. Tungsten also play critical role in these properties.

Stellite Alloy

| Stellite | Cobalt | Chromium | Tungsten | Iron | Nickel | Silicon | Molybdenum | Manganese | Carbon |

| Percent by Weight | BaL. | 25.0-30.0 | 2.0-15.0 | 3.00 | 3.00 | 2.00 | 1.00 | 1.00 | 0.25-3.30 |

Co-20Cr-15W-10Ni (ASTM F90)

| Co-20Cr-15W-10Ni | Cobalt | Chromium | Tungsten | Nickel | Iron | Carbon |

| Percent by Weight | BaL. | 20.0-23.0 | 7.0-15.0 | 10.0-22.0 | 3.00 | 0.10-0.60 |

Co-Ni-Cr-Mo MIM

Co-Cr-Ni-Mo Alloys exhibit outstanding resistance to aqueous corrosion, and other characteristics like: resistance to different forms of wear, high strength in wide temperature range.

Co-35Ni-20Cr-10Mo (ASTM F562)

| Co-35Ni-20Cr-10Mo | Cobalt | Chromium | Nickel | Molybdenum | Tungsten | Iron | Carbon | Nitrogen |

| Percent by Weight | BaL. | 20.0-30.0 | 9.0-35.0 | 5.0-10.0 | 2.00 | 3.00 | 0.80 | 0.10 |

Co-Cr-Mo MIM

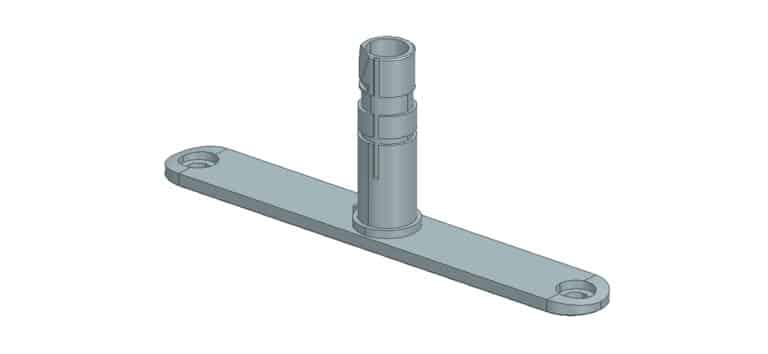

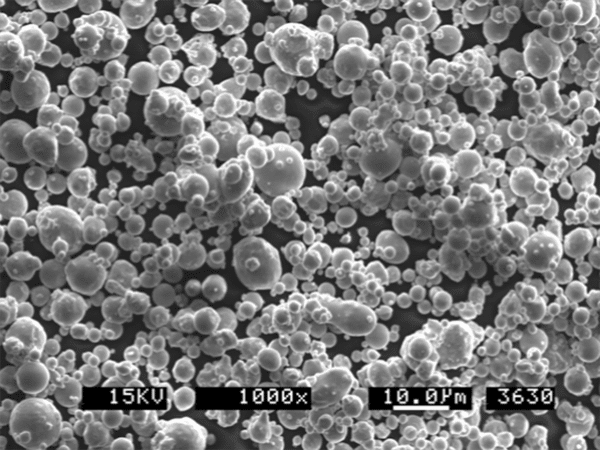

Co-28Cr-6Mo (F75) is applied for surgical implants, due to the high strength, superior corrosion-resistance, non-magnetic behavior, and bio-compatibility. Co-28Cr-6Mo in MIM process has the typical low carbon levels. This results in the small grain size and high fatigue strength, but poor wear resistance. Final high carbon content will increase the wear resistance, but give rise to poor fatigue strength.

SEM of Co-28Cr-6Mo Powder

Co-28Cr-6Mo (ASTM F75)

| Co-28Cr-6Mo | Cobalt | Chromium | Molybdenum | Nickel | Tungsten | Iron | Carbon | Nitrogen |

| Percent by Weight | BaL. | 27.0-30.0 | 5.0-7.0 | 0.50 | 0.20 | 0.75 | 0.35 | 0.25 |

Co-Alloy Application

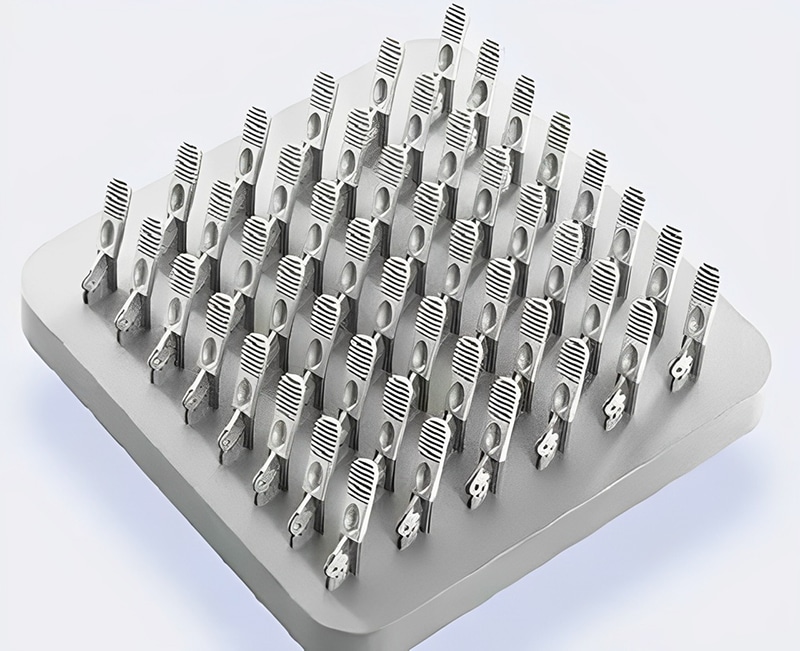

As the requirements of MIM component are becoming more demanding, particularly with strength, magnetic properties, corrosion resistance, wear resistance, surface quality. Co-alloys, as the advanced metallic materials, combine high corrosion resistance with excellent mechanical strength, wear resistance, specific magnetic properties (ferromagnetism, para-magnetism). F75 as the most common Co-Cr-Mo alloy, is applied widely for surgical implant, 3C components.

Conclusion

ZCMIM has more than 15 year experience in Cobalt MIM. We apply different alloy proportion, powder size, sintering parameter to achieve specific mechanical and magnetic properties. Contact us for your next Co MIM project.