Home » Blog

ZCMIM Blog

ZCMIM provides professional metal injection molding technology resources to optimize MIM design and manufacturing process.

Professional Metal Injection Molding Blog

MIM vs 3D Printing

Metal injection molding (MIM) vs Metal 3D printing (Addictive Manufacturing) are high competitive metal manufacturing technologies.

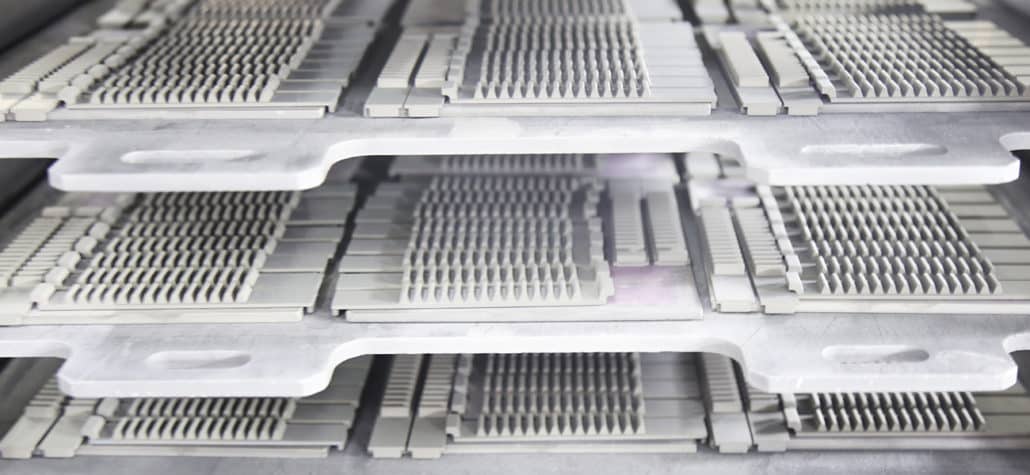

What are MIM Parts

What are MIM part, MIM Parts refers to metal components produced by metal injection molding process, which is a new metalworking technology.

How MIM Work

MIM mix metal powder with binder materials, mold into desired shape, then remove the binder materials and sinter into the final part.

What is Metal Injection Molding

Metal injection molding is a cost-effective metal manufacturing, we can consider some effective guidelines to achieve successful application.

MIM vs Machining

Metal injection molding (MIM) vs Machining technology have unique advantages and benefits in manufacturing process.

MIM vs PM

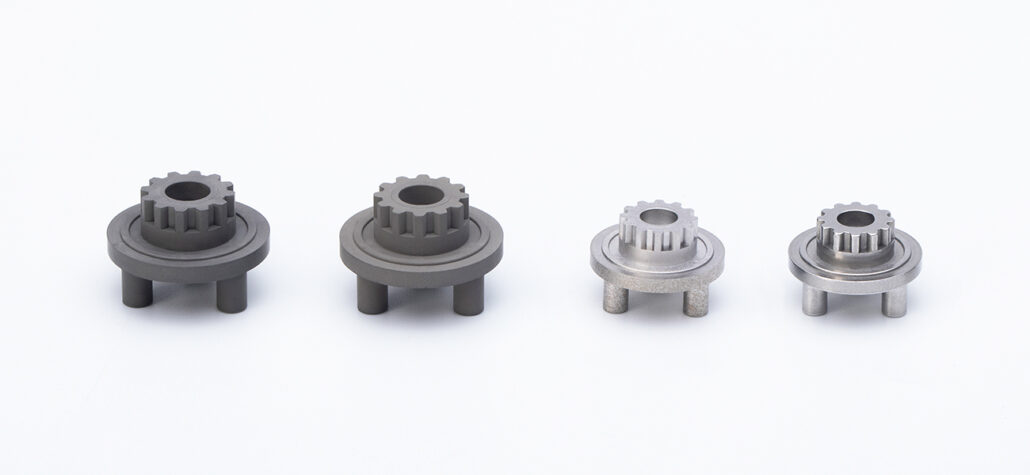

Metal injection molding (MIM)vs powder metallurgy (PM) are both powder based technology for metal parts with small-size and high quality.

Metal Injection Molding vs Die Casting

Metal Injection Molding vs Die casting witness MIM is an effective metalworking way to produce small-size parts with complex geometries.

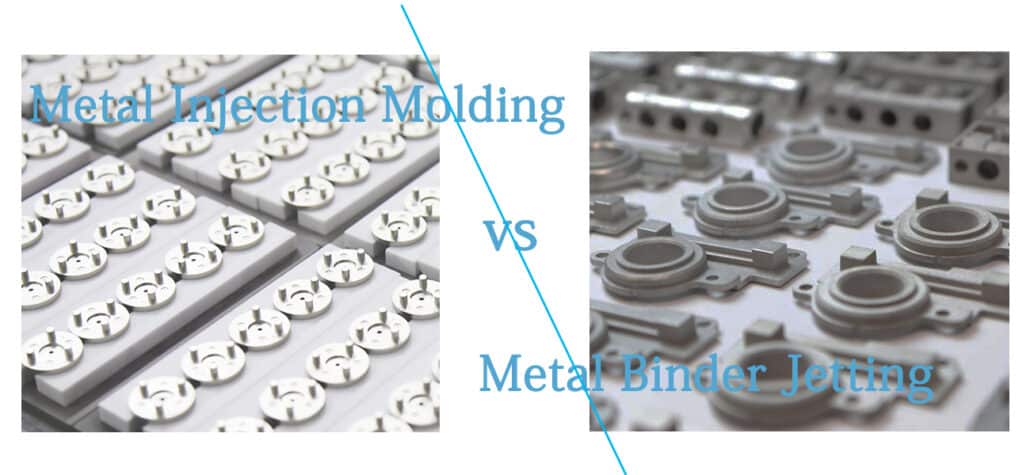

MIM vs MBJ

Metal Injection molding (MIM) vs Metal Binder Jetting (MBJ) have similar densifying processes of debinding and sintering.

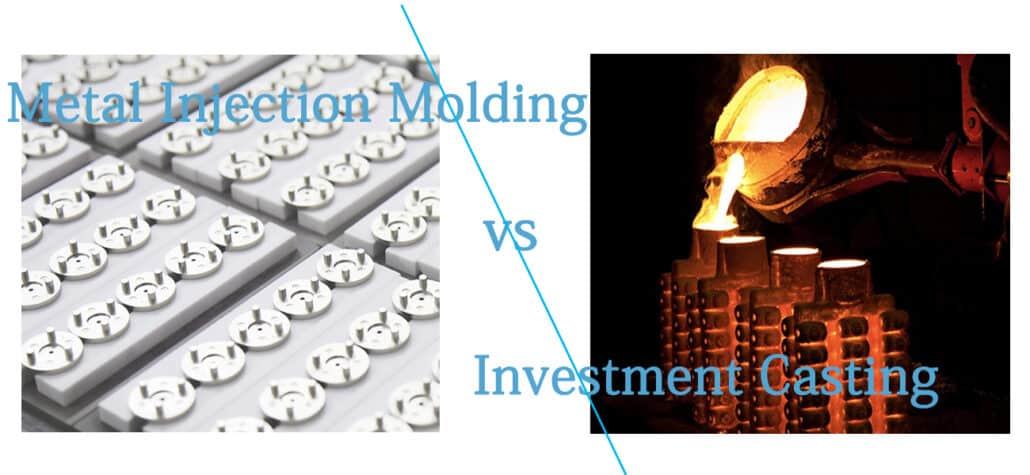

Metal Injection Molding vs Investment Casting

Metal injection molding (MIM) vs Investment casting (IC) are both cost-effective manufacturing technologies for high-quality metal components.

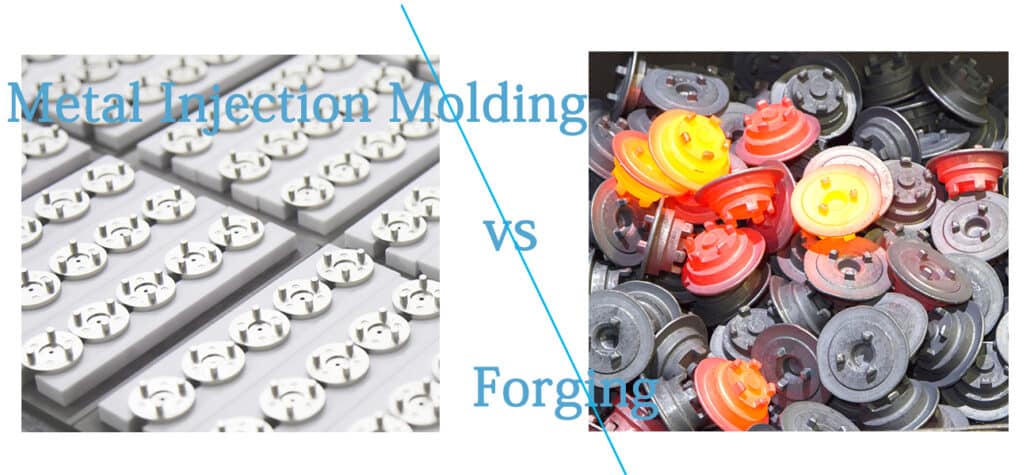

Metal Injection Molding vs Forging

Metal injection molding (MIM) vs Forging are two total different metalworking methods, result in different properties for final metal parts.

MIM Powder

Metal injection molding (MIM) powder is the basic of MIM feedstock, MIM power determines the sintering process and final propertie.

Powder Injection Molding

Powder Injection Molding (PIM) is a cost-effective manufacturing technology for high volume production of shaped components from powders.

MIM Polishing

MIM Polishing can be used widely for aesthetic improvement. In order to satisfy both mechanical and cosmetic requirements.

Debinding in MIM

Debinding is a crucial process in MIM, it will create a porous, fragile brown part without deformation and defects.

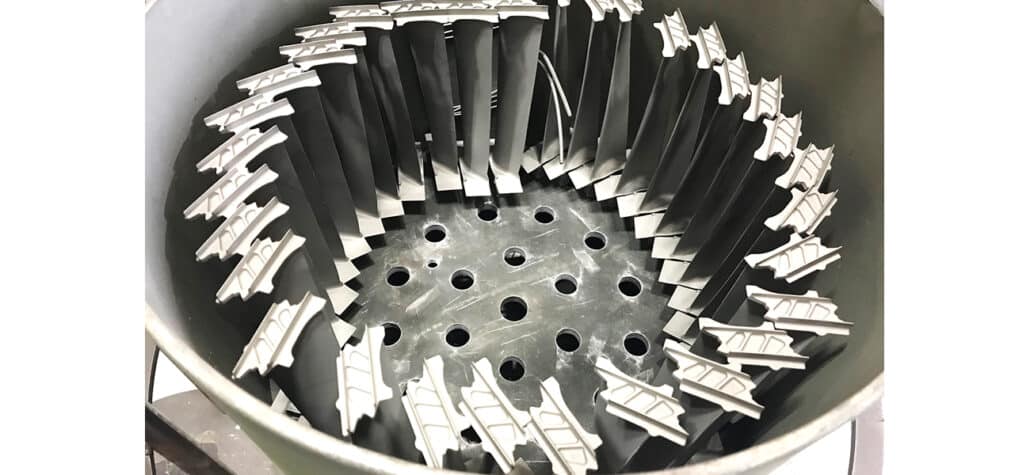

Sintering in MIM

Sintering process is the most critical step in MIM (metal injection molding). It determines the properties and tolerance of final parts.

MIM Feedstock

ZCMIM make sure all our MIM feedstock composition of metal powder & binder to achieve our required standards.

Custom MIM Materials

ZCMIM selects the right blend of MIM materials to create personalized component with highest standards and excellent properties.

Carbon Control in MIM

Carbon control is the fundamental factor for final component quality, the challenge of carbon element has strong influence in MIM technology.

Tool Steel MIM

Tool steels have significant potential applications in MIM industry and MIM-like manufacturing process.

Micro MIM

Micro MIM is an advanced technique of metal injection molding, it applies sub-μ metal powders and micro-size mold to produce tiny parts.

Hot Isostatic Pressing

Hot Isostatic Pressing (HIP) is a critical post-processing technology for the Metal Injection Molding (MIM) industry.

Iron-Nickel Alloy

The iron-nickel alloy (nickel-iron alloy) is abbreviated as FeNi or NiFe, it is a group of alloys with primary element of nickel (Ni) and iron (Fe).